In the demanding world of industrial sealing, a one-material-fits-all approach often falls short. Composite gaskets emerge as an innovative sealing solution by strategically combining the strengths of different materials, offering engineers and procurement specialists a more reliable and efficient choice. This comprehensive guide delves into the definition, primary types, core advantages, and wide-ranging applications of composite gaskets to empower your sealing decisions.

What is a Composite Gasket?

A composite gasket is a sealing element manufactured by combining two or more different materials, typically including both metal and non-metal components. This design aims to synergize the benefits of each constituent—such as the strength of metal and the conformability/sealability of non-metals—creating a product with performance far exceeding that of single-material gaskets. Common composite structures include spiral wound gaskets (metal windings with non-metallic filler) and metal-jacketed gaskets.

Thanks to this hybrid construction, composite gaskets exhibit excellent sealing performance alongside superior resistance to high temperatures, high pressure, and corrosion. Consequently, they are particularly suited for harsh sealing environments involving extreme temperatures, pressures, or corrosive media, making them the ideal choice for industries like petrochemicals, power generation, automotive, and heavy machinery.

Different Types of Gaskets

Composite gaskets can be categorized into several main types based on their core materials, each engineered for specific application demands.

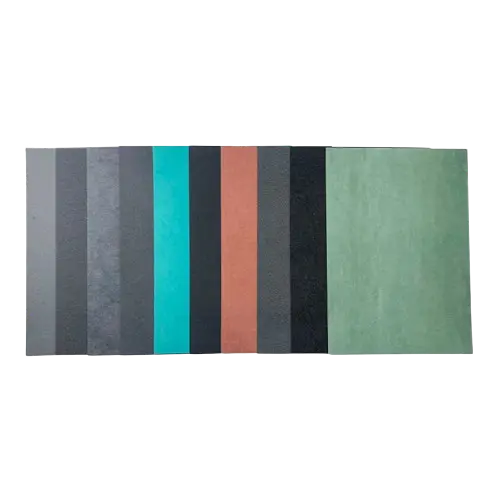

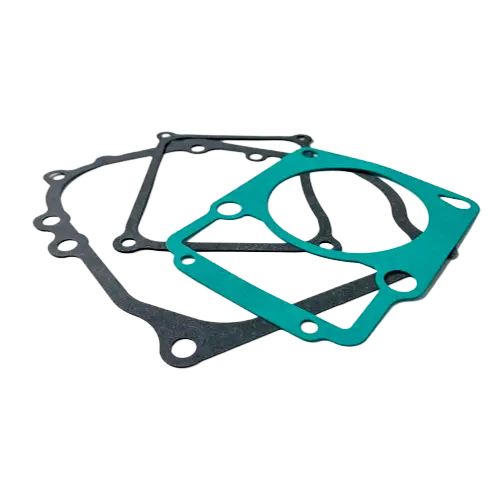

Non-Asbestos Composite Gaskets

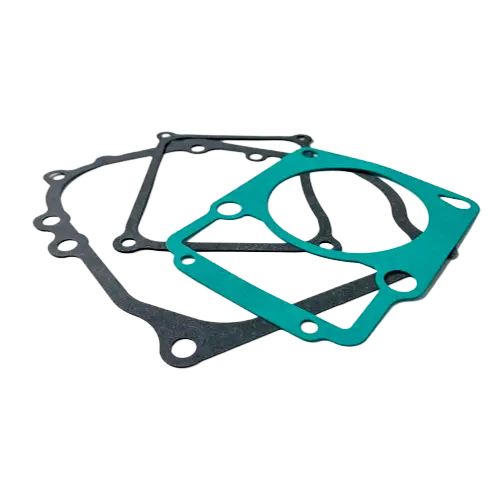

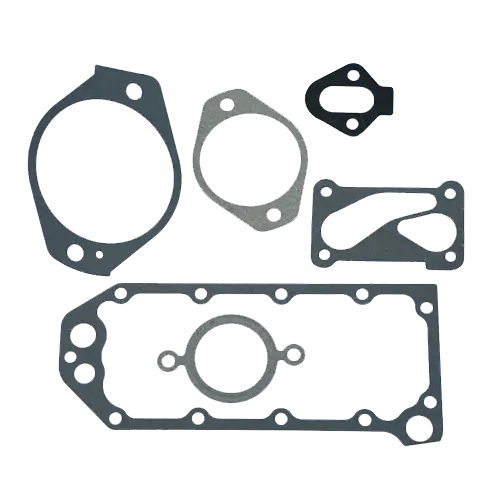

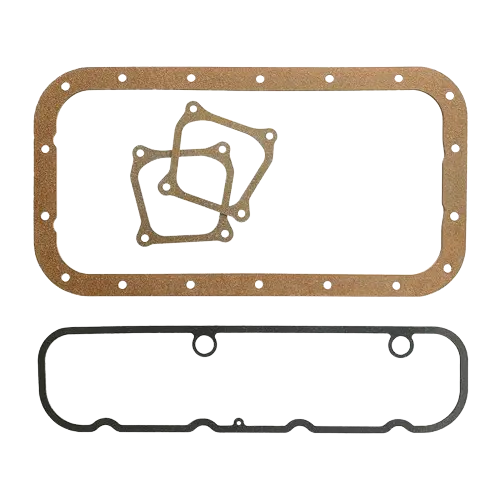

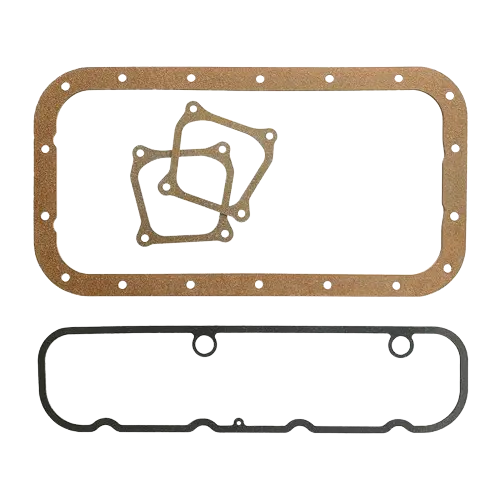

Non-asbestos composite gaskets serve as the modern, safer alternative to traditional asbestos gaskets. They are typically made by laminating and compressing non-asbestos fiber sheets with punched metal reinforcement plates.

Key Advantages: This structure provides high mechanical strength and dimensional stability while maintaining good compressibility and recovery. It reliably seals lubricants, fuels, and various coolants.

Typical Applications: Widely used in automotive engines, agricultural machinery, motorcycles, and engineering equipment for sealing applications such as oil pans and valve covers.

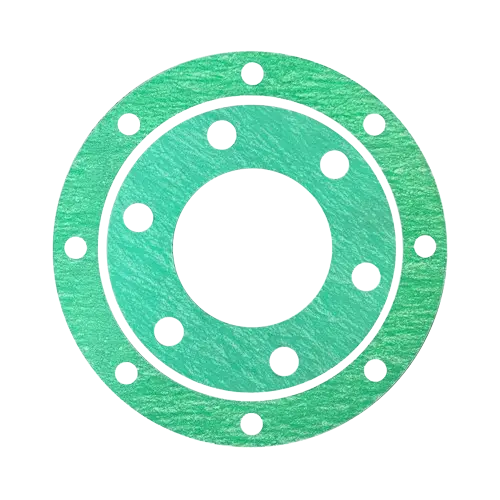

Graphite Composite Gaskets/Sheets

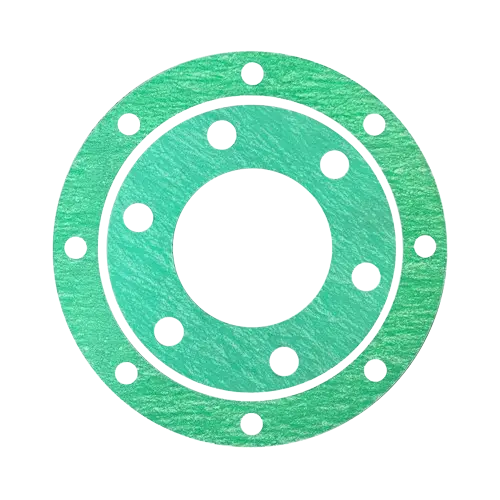

Graphite composite gaskets are high-performance sealing materials that marry the exceptional heat resistance and chemical inertness of flexible graphite with the structural reinforcement of a metal core (e.g., tanged metal plate) or composite layer.

Key Advantages: They offer outstanding performance in extreme conditions, including very high temperatures, and provide excellent sealing across a wide range of chemicals. Their durability ensures a long service life.

Typical Applications: Commonly used for cylinder head gaskets, exhaust system gaskets, and critical flanges in chemical processing and power plants.

Other Specialized Composite Gaskets

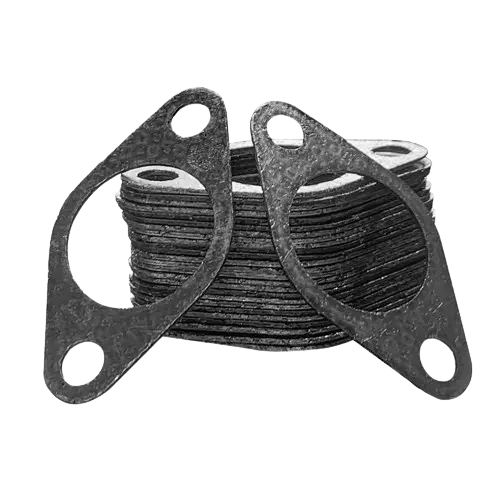

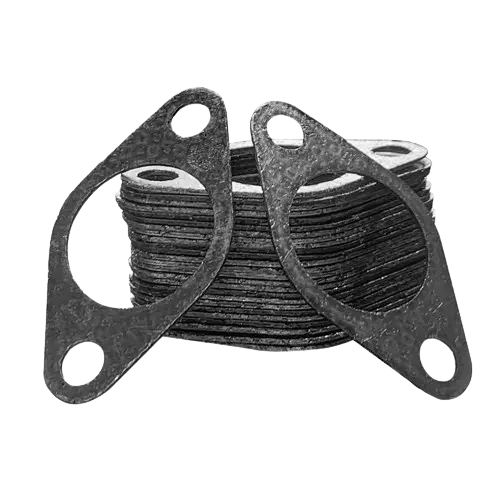

Cork-Rubber Gaskets: Combine the natural resilience and sealing ability of cork with the elasticity and fluid resistance of rubber (like NBR). Ideal for applications requiring a seal against fuels, oils, and water in environments with vibration or irregular surfaces, often found in automotive and general machinery.

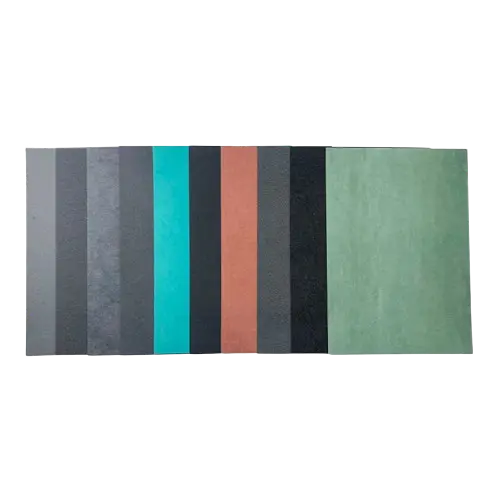

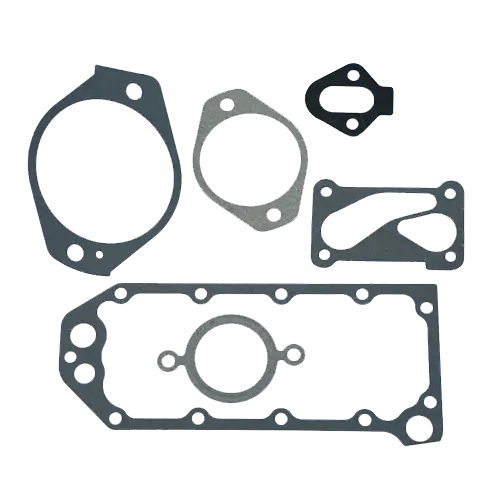

Compressed Non-Asbestos (CNA) Gaskets: Manufactured using a beater-addition process with high-quality non-asbestos fibers and binders, then compressed under high pressure. They offer good oil resistance, stability, and flexibility, serving as a direct, high-performance replacement for asbestos gaskets in many general industrial applications.

Advantages of Composite Gaskets

Composite gaskets have become a cornerstone in industrial sealing due to their multifaceted benefits that address the limitations of traditional gaskets.

Superior Sealing Performance: The combination of materials allows for better conformance to flange surfaces, creating a more effective leak-proof seal against high pressure and temperature fluctuations.

Enhanced Durability & Strength: Reinforcing materials (like metal) significantly increase the gasket's tensile strength and blow-out resistance, allowing it to withstand much higher bolt loads and system pressures.

Excellent Temperature and Chemical Resistance: By selecting appropriate facing materials (e.g., graphite, PTFE), composite gaskets can operate reliably in a broader range of temperatures and resist a wider array of corrosive media than many homogeneous gaskets.

Cost-Effectiveness in the Long Run: While the initial cost may be higher, their longer service life, reduced maintenance downtime, and superior reliability lead to lower total cost of ownership.

Customizability & Design Flexibility: They can be engineered by varying materials, thickness, and density to meet specific application requirements for compression, recovery, and fluid compatibility.

Environmental & Safety Compliance: The prevalent use of non-asbestos materials aligns with global environmental regulations and provides a safer workplace, reducing health risks associated with asbestos exposure.

Many composite gaskets use non-asbestos materials, making them a safer and more environmentally friendly choice. For companies that comply with environmental standards and regulations, using composite gaskets is a more sustainable solution. As a gasket manufacturing company, Junma provides a variety of seals and gaskets.

Critical Applications of Composite Gaskets

The robust properties of composite gaskets make them indispensable across numerous industries:

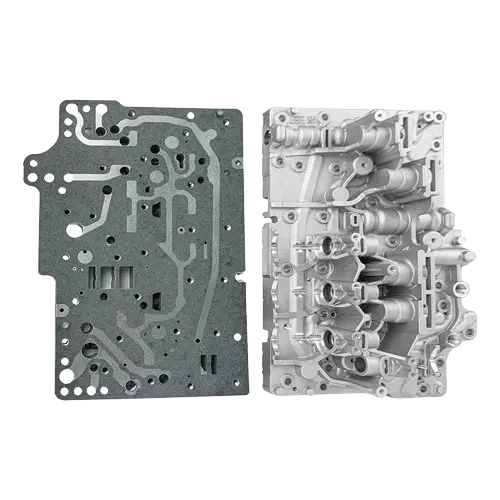

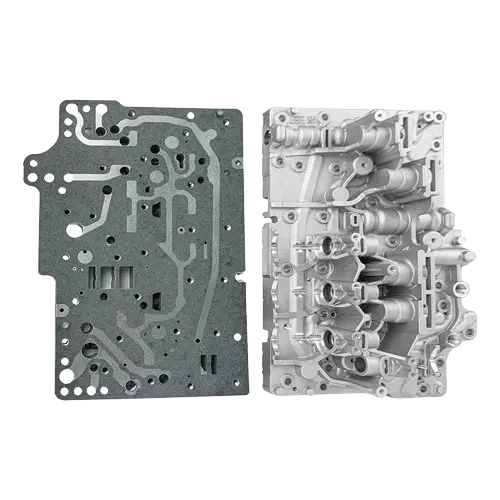

Automotive & Transportation: For critical engine components (cylinder heads, exhaust manifolds), transmission systems (valve body gaskets), and fluid systems.

Oil, Gas & Petrochemicals: Sealing flanges, valves, and reactors in pipelines and refineries handling high-pressure, high-temperature, and corrosive hydrocarbons.

Power Generation: In boilers, steam turbines, and heat exchangers within thermal and nuclear power plants.

General Industrial & Heavy Machinery: Pumps, compressors, and agricultural machinery requiring reliable sealing for lubricants, hydraulic fluids, and coolants.

How to Select the Right Composite Gasket?

Choosing the correct composite gasket is vital for system safety and efficiency. Consider these factors:

Operating Conditions: Clearly define the temperature range, pressure (both steady and cyclic), and the chemical composition of the media being sealed.

Flange Specifications: Consider the flange material, surface finish, bolt load, and design (e.g., raised face, flat face).

Performance Requirements: Determine the needed level of sealability, compressibility, recovery (creep relaxation resistance), and blow-out resistance.

Regulatory & Safety Standards: Ensure the selected materials comply with industry-specific and environmental regulations (e.g., non-asbestos mandates, FDA, RoHS).

Consult with Experts: Partner with a technical sealing supplier like Chengdu Junma Sealing. Our engineers can help analyze your application and recommend the optimal composite gasket material and design from our extensive range, including our high-performance E-Series and S-Series non-asbestos sheets.

In summary, composite gaskets are the ideal choice for many industrial applications due to their multifunctionality, high performance, customizability, cost-efficiency, superior sealing performance, and environmental friendliness. They not only enhance the efficiency and safety of equipment but also reduce long-term maintenance costs for enterprises, becoming a critical material in the modern industrial sealing field.