What is a fiber gasket?

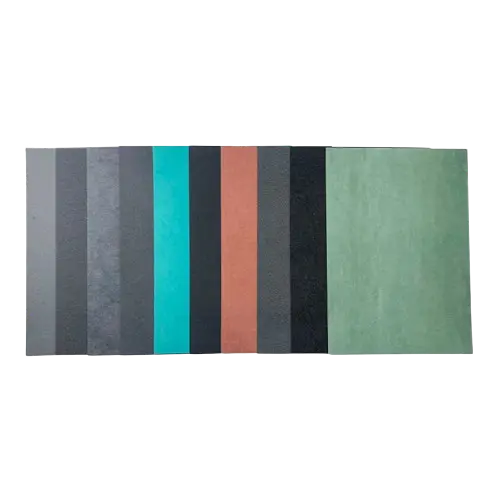

Fiber gaskets are versatile sealing components primarily made from non-metallic fibers, often combined with binders and fillers through processes like the beater-adddition or compression molding. Unlike solid rubber or metal gaskets, their fibrous structure provides a unique balance of conformability and resilience. When compressed between two surfaces (like flanges), the fibers compact and create a tight, often maze-like barrier that effectively seals against fluids and gases. Key properties driving their function include compressibility to fill surface imperfections, recovery to maintain seal under vibration, and tensile strength to resist pressure and blow-out. They are fundamental in creating reliable static seals where flexibility and medium pressure resistance are required.

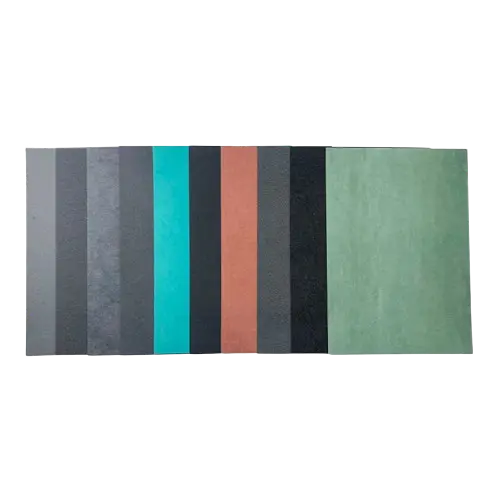

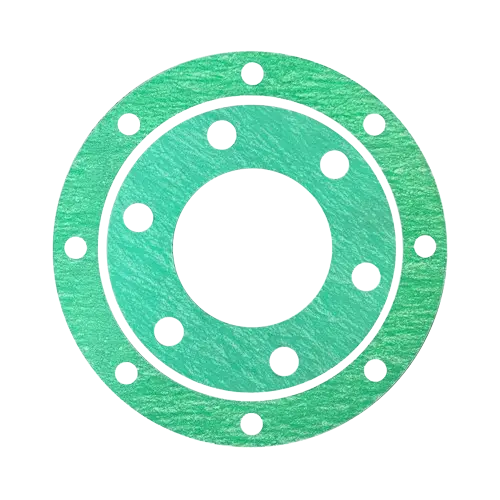

Compressed Non-Asbestos (CNA) Fiber Gaskets: The Modern Standard

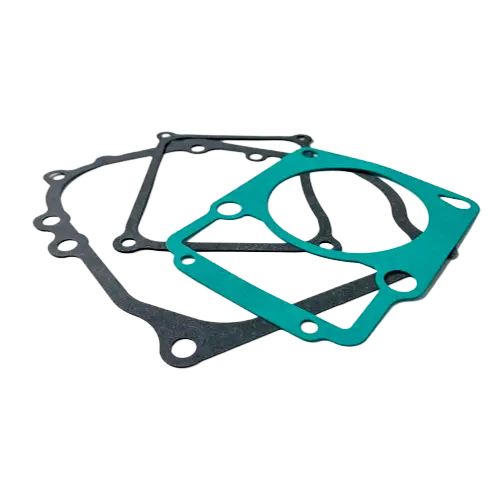

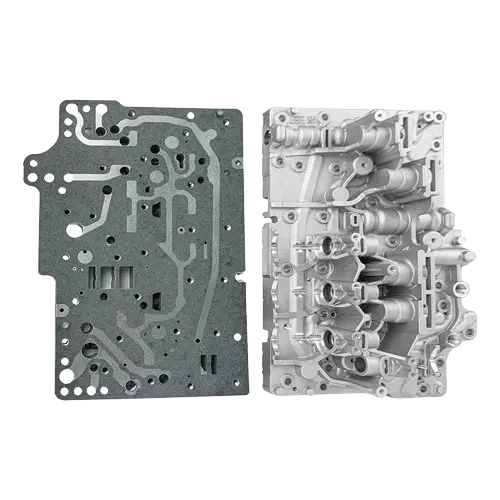

Compressed Non-Asbestos (CNA) fiber gaskets are the engineered, high-performance successors to traditional asbestos gaskets. Manufactured using a controlled beater-addition process that blends high-grade organic and synthetic fibers (like aramid or cellulose) with elastomeric binders, they are then cured under high heat and pressure into uniform sheets.

This process creates a dense, consistent material structure that offers superior oil and fuel resistance, excellent temperature stability, and reliable sealing performance without the health hazards of asbestos. CNA gaskets are the go-to choice for sealing engines, pumps, and general industrial machinery, providing a safe, durable, and legally compliant sealing solution for lubricants, coolants, and moderate-temperature hydrocarbons.

High-Temperature & High-Performance Fiber Gasket Materials

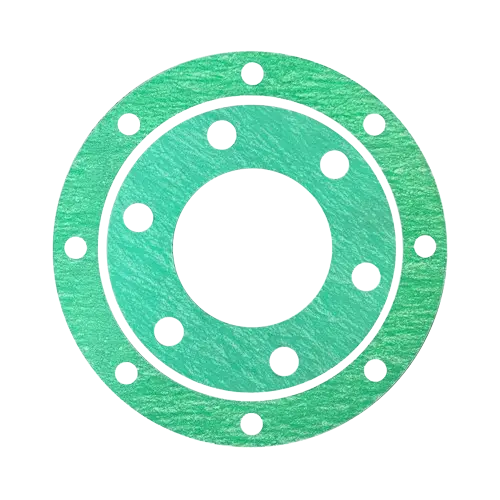

For extreme environments, specialized fiber materials are engineered to maintain integrity where others fail. High-temperature fiberglass gasket materials, often impregnated with graphite or PTFE, excel in applications up to 1000°F (538°C), providing excellent thermal insulation and corrosion resistance for exhaust systems, boilers, and furnace flanges.

For the most demanding mechanical and chemical challenges, aramid fiber gaskets offer an exceptional strength-to-weight ratio, outstanding wear resistance, and stability across a wide temperature range. These premium materials are critical in aerospace, high-performance automotive, and chemical processing industries, where failure is not an option and sealing under extreme stress, temperature, and chemical exposure is paramount.

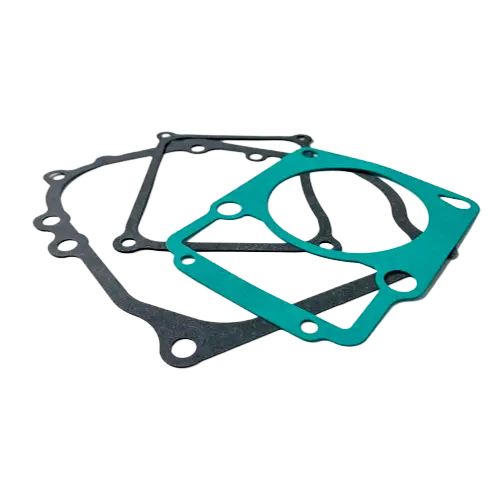

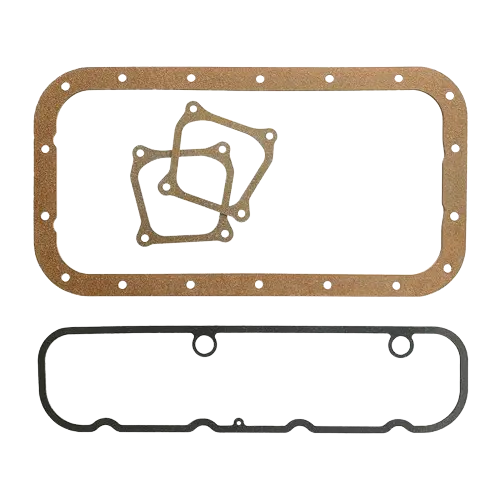

Rubber-Fiber Composite Gaskets: Flexibility Meets Strength

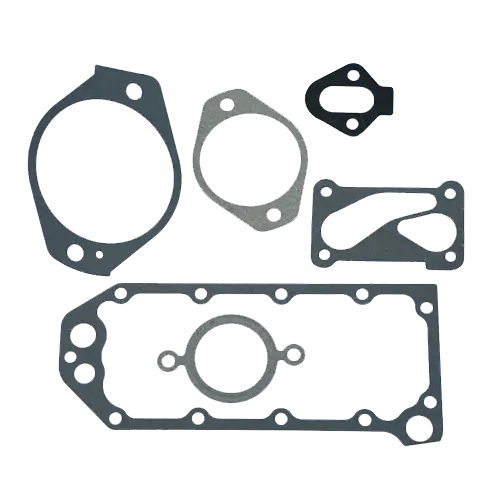

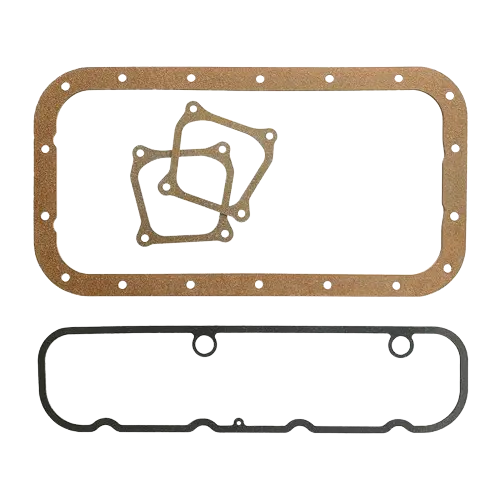

Rubber-fiber composite gaskets, such as cork-rubber or synthetic fiber-rubber blends, are designed to solve sealing challenges that require both conformability and structural integrity. In this composite structure, the fibrous material (like cork or cellulose) provides compressive strength, dimensional stability, and resilience, while the rubber matrix (commonly NBR or SBR) contributes elasticity, enhanced fluid resistance, and improved sealing against irregular surfaces.

This synergy makes them ideal for applications with vibration or thermal cycling, such as in gearbox covers, oil pans, and access panels in automotive and general machinery. They effectively seal against oils, water, and fuels, offering a robust solution where a pure rubber or pure fiber gasket alone would be insufficient.

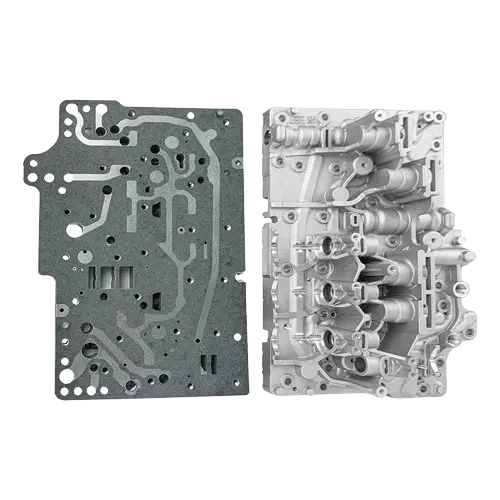

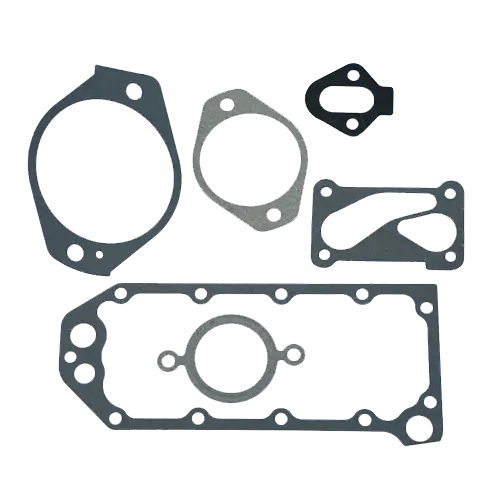

Applications of Fibre Reinforced Gaskets in Various Industries

Selecting the correct fiber gasket is crucial for system safety, longevity, and cost-effectiveness. Follow this decision framework:

Analyze the Medium & Temperature: Identify the chemical compatibility and continuous operating temperature. CNA gaskets handle most oils and coolants up to ~400°F (204°C), while fiberglass handles higher heat with specific chemical limits.

Assess Pressure & Flange Conditions: Determine the internal pressure and flange surface finish. Higher-strength materials like aramid-reinforced sheets are better for high bolt loads and rough flanges.

Define Key Priorities: Balance needs for sealability, compressibility (to fill gaps), recovery (for cyclic loads), and anti-stick properties for easy maintenance.

Consult Standards & Regulations: Ensure the material meets industry-specific standards (e.g., ASTM F104, FDA, RoHS) and internal safety protocols, especially for food, potable water, or emissions-controlled equipment.

Advantages of fiber gaskets

Economic efficiency

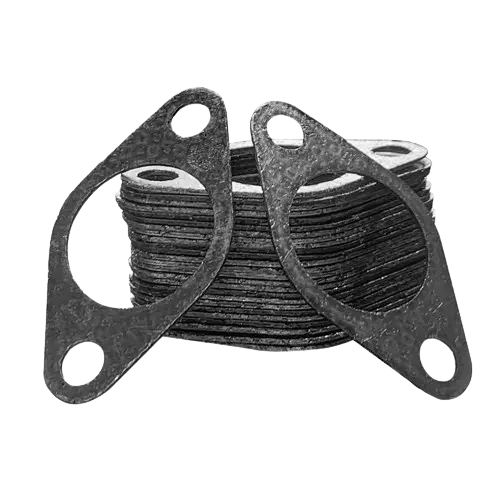

Compared to other types of gasket materials such as metal or rubber, fiber gasket is typically more economical. This cost advantage makes them an ideal choice for large-scale applications, providing a cost-effective sealing solution for scenarios that require a significant number of gaskets.

Corrosion resistance

Depending on the fiber materials used, fiber gaskets exhibit excellent resistance to various chemicals, oils, and fuels. Therefore, they are particularly suitable for environments where they may come into contact with corrosive or erosive substances.

High-temperature resistance

Fiber gaskets can withstand medium to high-temperature conditions, with performance depending on the specific material composition. Some specially designed fiber gaskets can operate stably in high-temperature environments, making them ideal for use in engines, exhaust systems, and other high-heat load equipment.

Convenience

Fiber gaskets are easy to process; they can be cut or molded to specific sizes to meet different application requirements. Their installation and replacement process is quick and easy, helping to reduce downtime and maintenance costs.

Protection of contact surfaces

Due to the relatively soft nature of fiber gaskets, compared to harder materials like metal, the risk of damage to contact surfaces during installation or removal is lower. This helps maintain the integrity of the mating surfaces and extends the equipment's service life.

Environmental and safety compliance

Modern fiber gaskets mostly use asbestos-free materials, complying with regulations and standards related to environmental protection and worker health. This makes them an environmentally friendly and safe choice, helping companies fulfill their social responsibilities.

In summary, fiber gaskets integrate economic efficiency, durability, and safety, making them widely used in various sealing applications. They are a reliable sealing solution.