Gasket Material

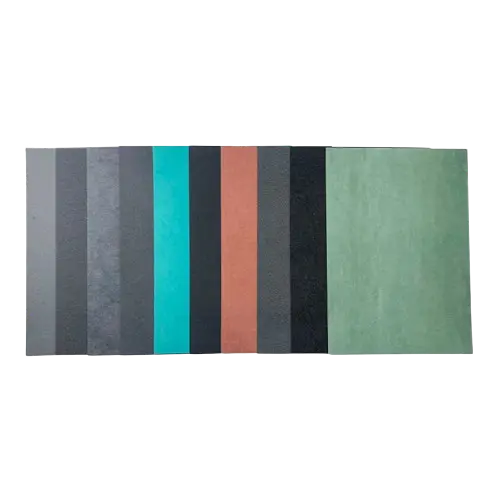

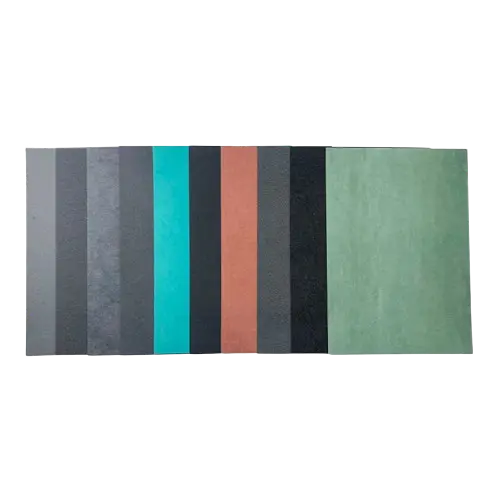

Non Asbestos Gasket Paper

Compressed Non Asbestos Gasket Material

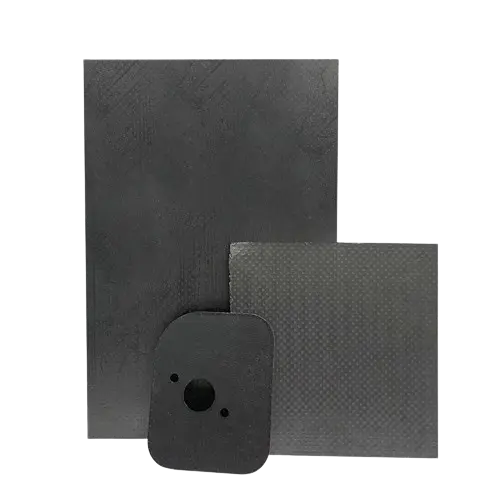

Oil Resistant Gasket Material

Cork Material

High Temp Gasket Material

Composite Gasket Material

Metal Coating Materials

Cost-effictive Gasket Paper E series E01/E02/E03

Expandable Materials Gasket Paper S Series S01/S02/S03

General Gasket Paper G Series G01/G02/G03

High-Performance Gasket Paper H Series H01/H02/H03

Composite Gasket Paper C Series C01/C02/C03

General Compressed Sheet Material 7102/ 7103/7104/7105

High Performance Compressed Sheet Material 7107/7108/7110

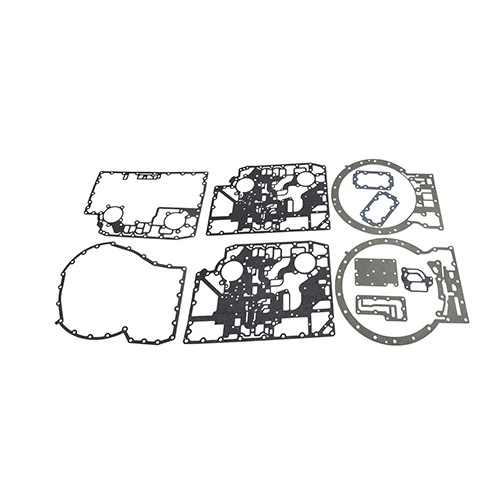

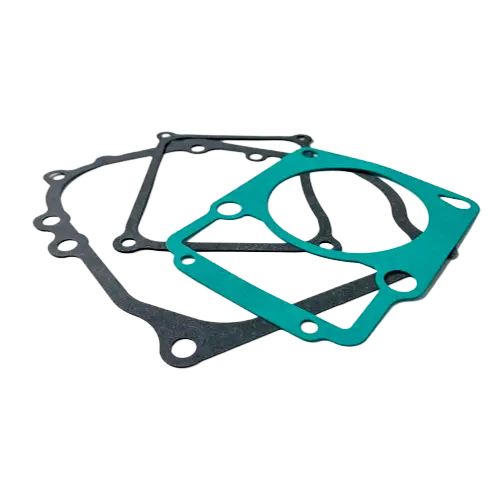

Custom Gasket

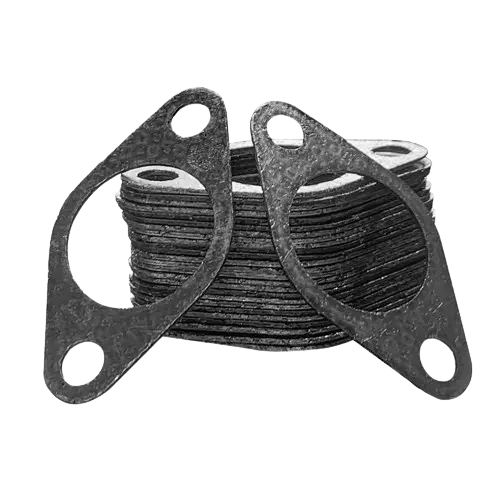

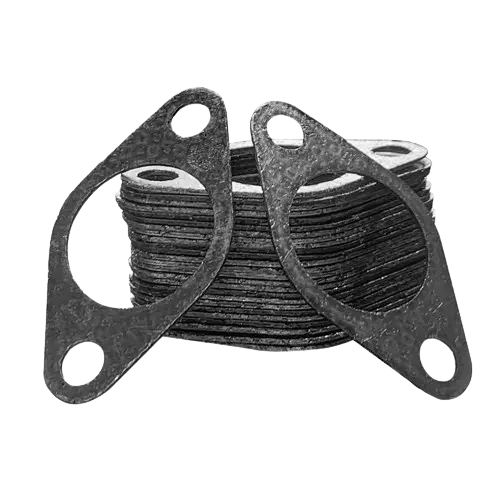

Fiber Gasket

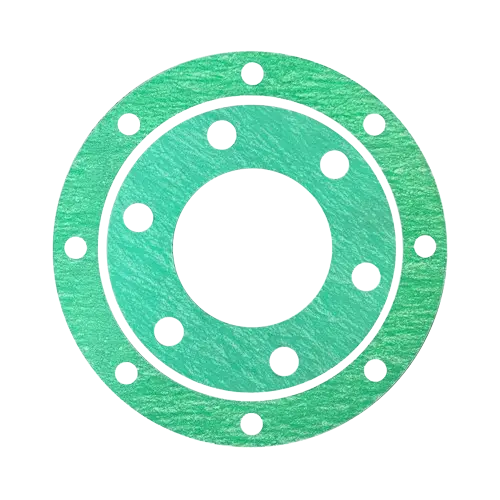

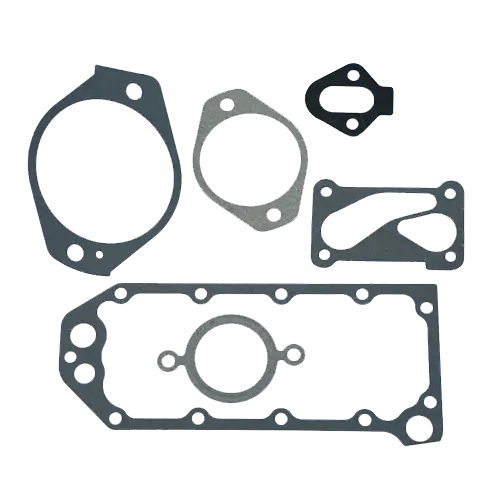

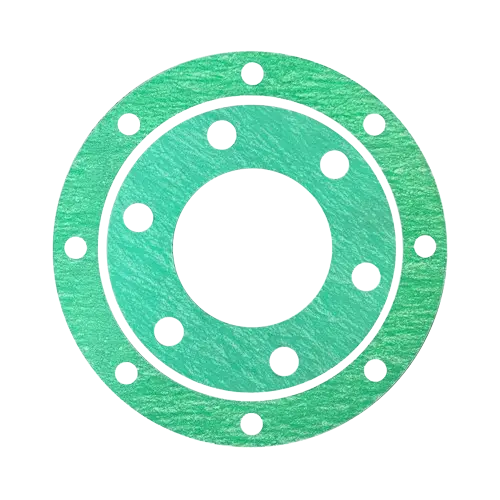

Flange Gasket

Graphite Gasket

High Temp Gasket

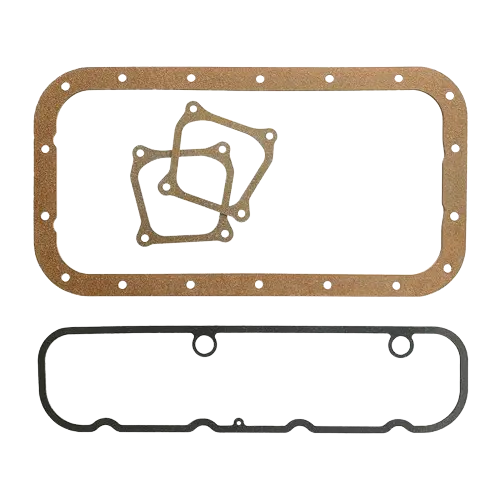

Cork Rubber Gasket

Oil Resistant Gasket

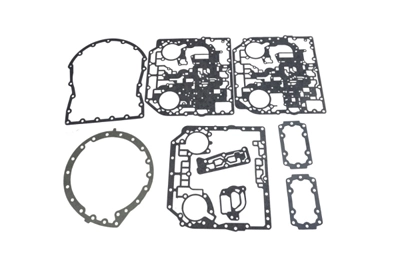

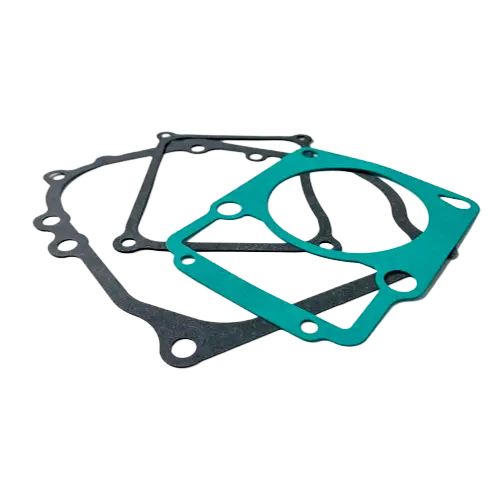

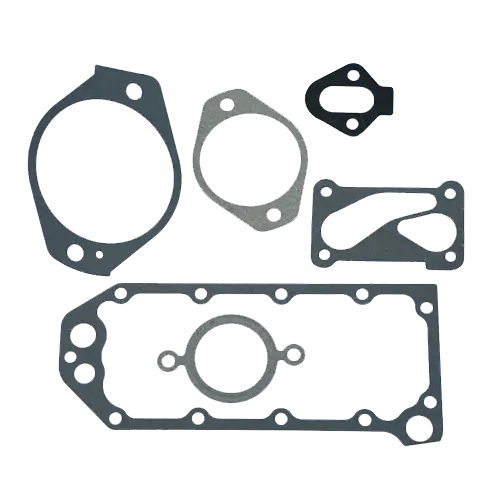

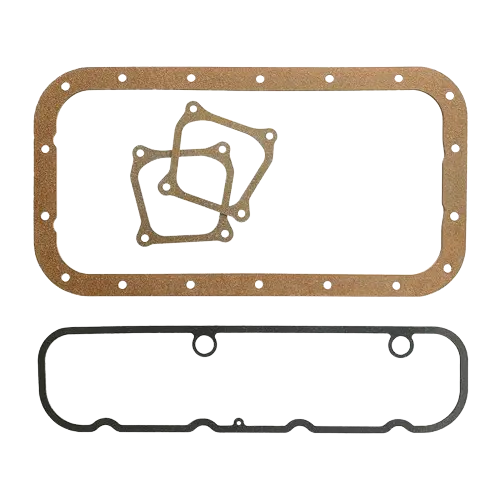

Engine Repair Kit

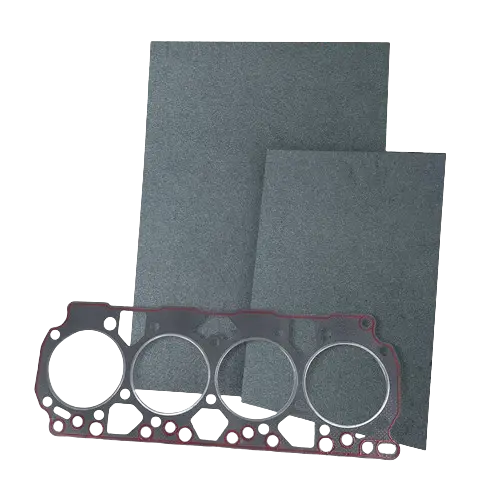

Compressed Non Asbestos Gasket

Fiber gasket is produced of non-asbestos fiber gasket material. These gasket materials are produced by the beater-addition process. In general, fiber gasket materials have good oil resistance, stability and flexibility, We offer a variety of materials with varying densities, expansion, and compressibility. The main applications of Fibergasket are automotive, motorcycles, trucks, compressors, general machinery, ship and pump etc.

A flange gasket is a gasket specifically designed to provide a seal between two flange faces, which are used to join pipes, valves, or other equipment together.

These gaskets are typically made from various materials, such as rubber, fiber, or metal, depending on the application and the requirements for sealing, temperature resistance, and chemical compatibility.

Graphite composite gasket is also named flexible graphite metal reinforced composite gasket or high-strength graphite gasket, is a sealing gasket made of punched metal tanged plate or punched metal core plate, metal mesh and flexible graphite particles. It is usually cut from flexible graphite composite reinforced plate.It is offen used for cylinder head gasket and exhaust gasket.

A high-temperature gasket is a type of gasket specifically designed to withstand elevated temperatures without losing its sealing properties or degrading.

These gaskets are used in applications where there is a need to seal joints or connections that are exposed to high temperatures.

A cork rubber gasket, also known as a cork-rubber composite gasket, is a type of gasket that combines the properties of cork and rubber materials.

It is made by bonding layers of cork and rubber together to create a durable and flexible sealing material.

Our oil-resistant gaskets are engineered to withstand the toughest environments where oil and petroleum-based fluids are present Manufactured from premium quality materials.

these gaskets are designed to provide exceptional sealing performance, durability, and resistance against swelling, heat, and chemical wear.

A compressed non-asbestos gasket, also known as CNA gasket, is a type of gasket material that is designed to replace traditional asbestos-based gaskets.

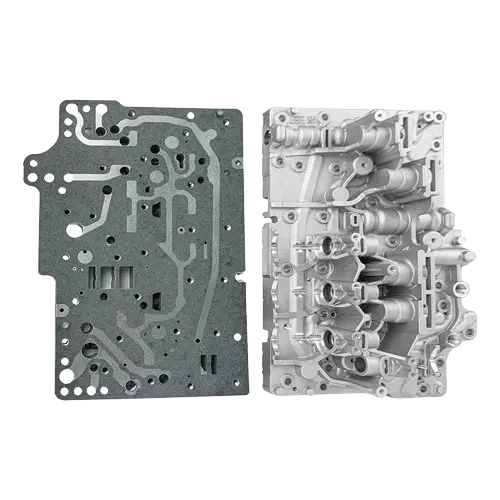

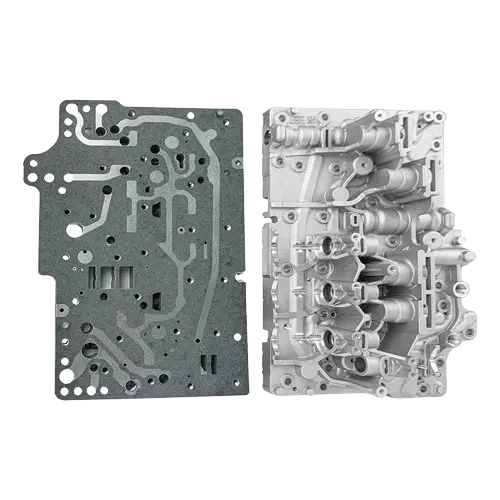

Transmission Material

The transmission valve body gasket is a crucial component in the complex system of an automatic transmission. This gasket serves as a seal between the valve body and the transmission casing, ensuring that hydraulic fluid does not leak from the system.

The clutch friction plate, also known as the clutch disc, is a crucial component in the clutch assembly of a manual transmission vehicle. It plays a vital role in the operation of the clutch system, enabling the smooth engagement and disengagement of the engine from the drivetrain.

Blog

Why Choose an Excellent Sealing Material Supplier

The Universal Standard: Why Model E03 is the “Go-To” Non-Asbestos Sheet for Everyday Sealing

Advantages of Junma Wet Paper Based Friction Materials

Guardians of agricultural mechanization: The critical role of gaskets

In the production process of asbestos

To ensure the sealing performance of asbestos

The specific application of asbestos

The production process of asbestos

Advantages of Non Asbestos Gasket Paper: A Comprehensive Guide

Asbestos-Free Sealing Materials: A Milestone in Safety and Sustainability

Automotive Spare Parts Sector Thriving with the Advent of Static Sealing Technology

Junma: Specialized in Manufacturing Sealing Materials

The Importance of Choosing the Right Gasket Material

Enhancing Efficiency with Reliable Transmission Material: Exploring Junma's Cutting-Edge Solutions

Enhancing Industrial Safety with Compressed Non Asbestos Gasket Material

Unveiling Junma: Revolutionizing Oil Resistant Gasket Material

Why Choose Composite Gasket Material?

Current Status of Non-Asbestos Gasket Material

Exploring Sealing Components: Oil-Resistant Gaskets

Overview of Non-Asbestos Gasket Application

What is Graphite Composite Sheet and Its Uses

Characteristics, Applications, and Precautions for Using Non-asbestos Gaskets

Importance of Gasket Compliance and Compressibility

Types and characteristics of asbestos-free sealing materials

Application Areas of Asbestos-free Sealing Materials

There are significant differences in the requirements of different cars for gaskets, and these differences are mainly reflected in the following aspects

Asbestos-free gaskets have the following advantages over conventional gaskets, and these advantages are also supported by the latest news and research

The cost-benefit analysis of asbestos-free gaskets can be considered from the following aspects

How Much Do You Know about the Fiber Gasket?

Introduction to Composite Gaskets

Introduction to Oil Resistant Gaskets and Oil Resistant Gasket Materials

Introduction of Heat Resistant Gaskets and Materials

Advantages of NBR Gasket Material

Selection and Application of Marine Gasket Materials

The Importance of Fuel Resistant Gasket Paper in Industry

Characteristics of Cork Rubber Gasket Material

Compressed Non-Asbestos Fiber Gasket Materials and Characteristics

How to Choose a Suitable Fiber Sealing Material

Tensile Strength of Sealing Materials

Relationship between Gasket Performance and Gasket Material Performance

Asbestos-free Fiber Gaskets

Cost-Effective Sealing: Why the E-Series Non-Asbestos Sheet is the Smart Choice for General Industry

S-Series (S01, S02, S03): Controlled-swell sealing material Non-Asbestos Sheets

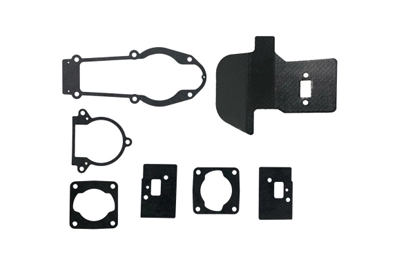

Junma High-performance sealing materials for outdoor power equipment

English

English Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português