Introduction to Compressed Non Asbestos Gasket Materials

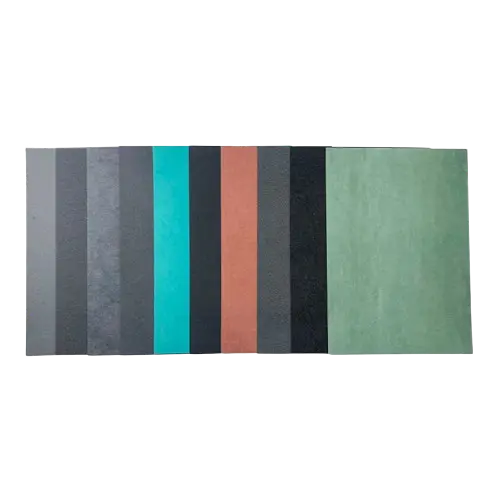

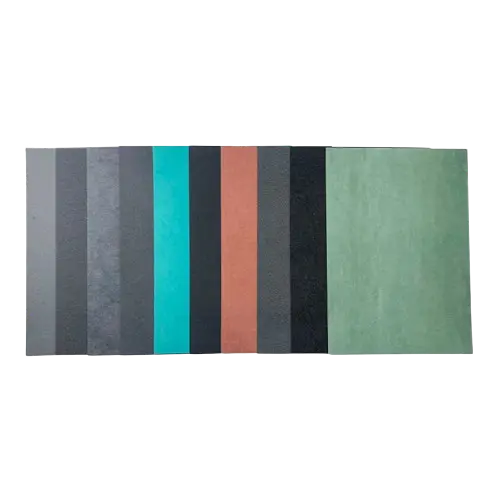

Compressed non asbestos gasket material is an eco-friendly sealing material based on high-performance aramid fibers, combined with high-temperature resistant rubber, glass fibers, heat-resistant inorganic fibers, and various functional fillers, formed through high-temperature pressing and precise formulation. This material does not contain asbestos and meets the current green production standards, making it an ideal substitute for traditional asbestos gaskets.

This material boasts excellent mechanical strength, chemical stability, and high-temperature resistance, making it suitable for a wide range of high-temperature, high-pressure, and corrosive media sealing applications. It is one of the indispensable sealing solutions in modern industrial fields.

Characteristics of Compressed Non-Asbestos Fiber Gaskets

Excellent sealing performance: Compressed non-asbestos fiber gaskets possess good air tightness and liquid tightness, effectively preventing media leakage. They can maintain a stable sealing state even during long-term operation.

High temperature and corrosion resistance: The material can withstand high temperatures, with some models resistant to temperatures above 300°C. It also exhibits excellent corrosion resistance to media such as oils, acids, alkalis, seawater, and steam.

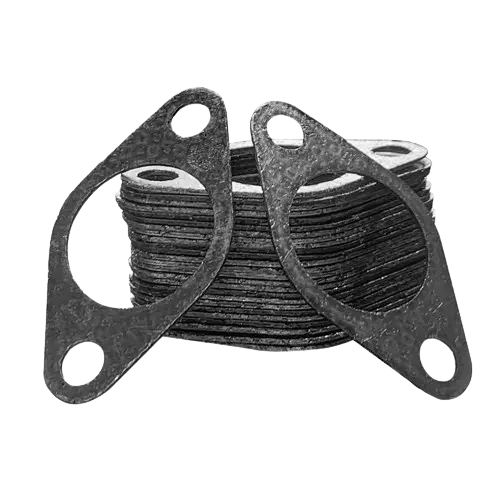

Good mechanical strength and resilience: It has good compressive strength and recovery capability, maintaining its shape and sealing effect even under repeated compression, thereby effectively extending its service life.

Eco-friendly and safe: The material is asbestos-free, avoiding the health hazards of asbestos dust, and complies with environmental standards such as ROHS and REACH, making it a representative product of green sealing materials.

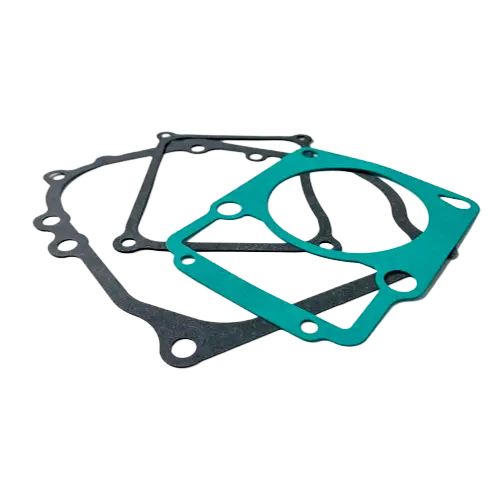

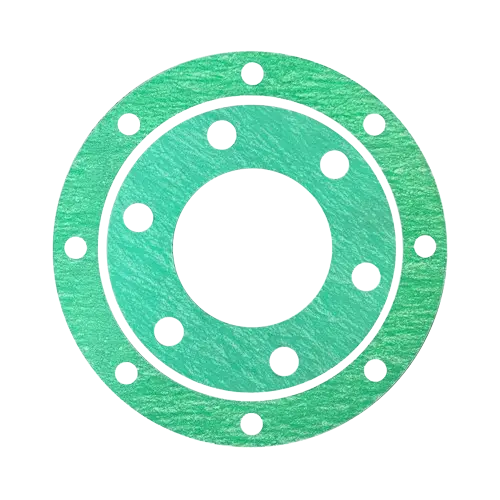

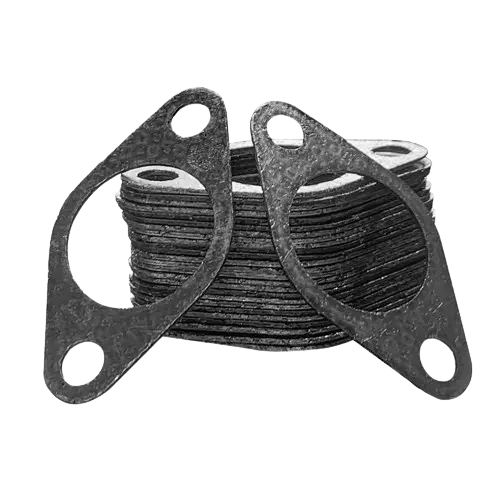

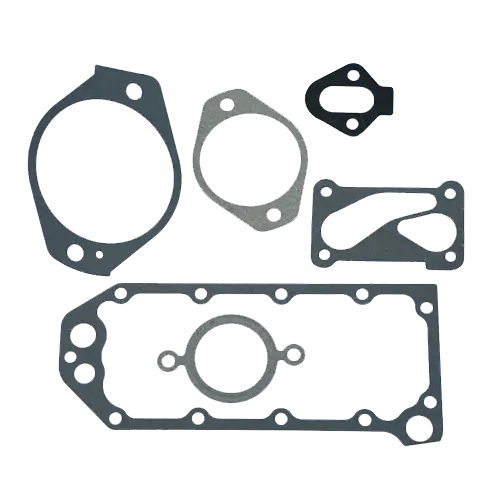

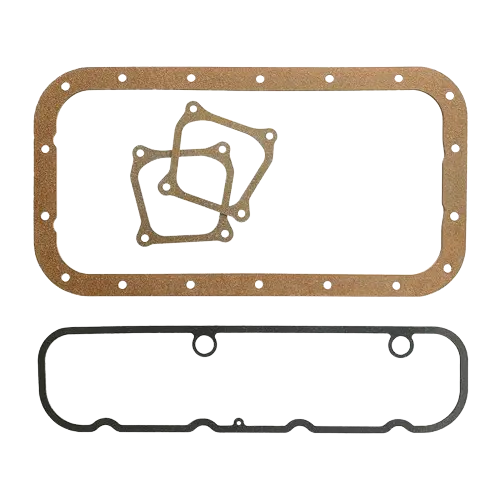

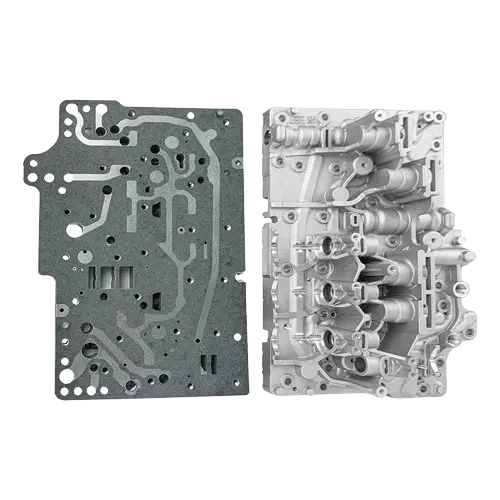

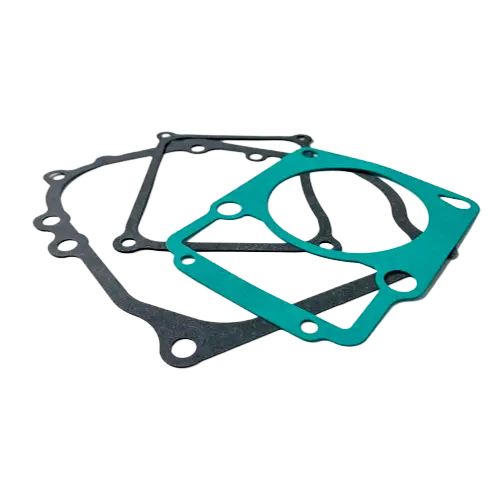

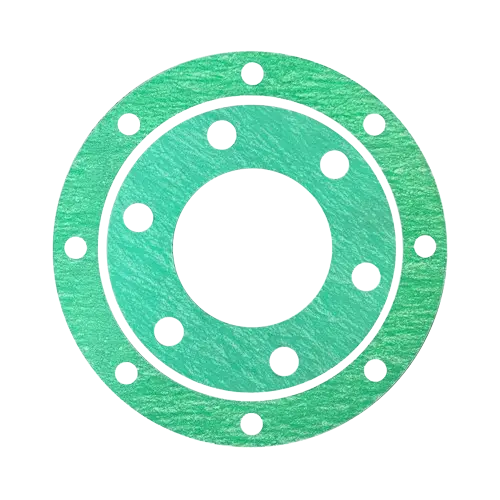

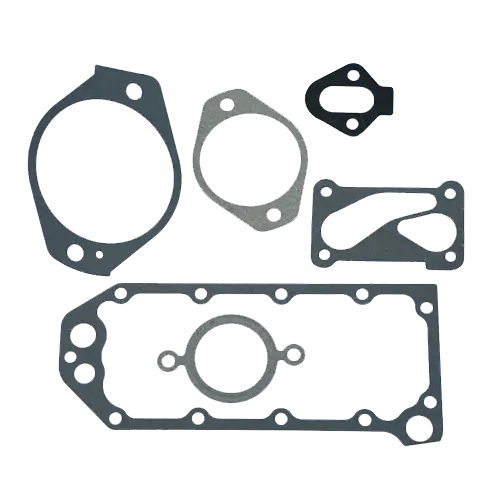

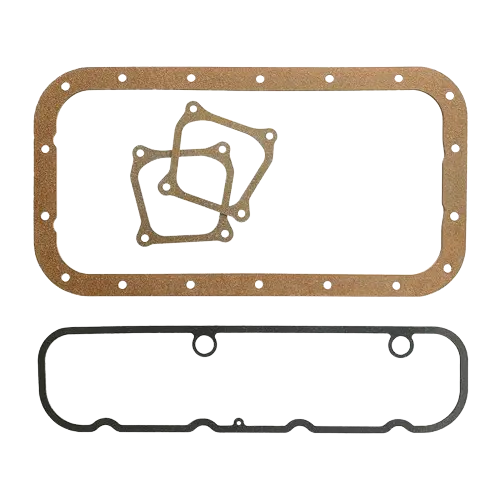

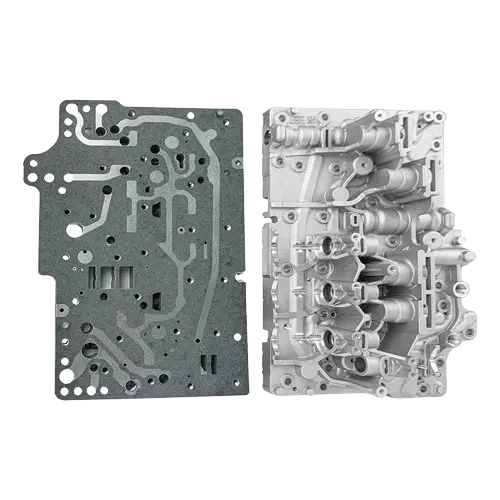

Outstanding processing performance: Compressed non asbestos gasket material is easy to stamp and cut, and can be processed into sealing gaskets of various sizes and shapes according to different usage environments.

Application Fields of Compressed Non-Asbestos Fiber Gaskets

Due to its excellent performance and adaptability, compressed non-asbestos fiber gaskets are widely used in the following industries and scenarios:

Petrochemical industry: Used for flange sealing and pipeline connections, its corrosion resistance meets the high requirements of chemical media.

Marine and offshore engineering: Suitable for marine, high-humidity, and high-salinity environments, commonly used in ship engines and pipeline system seals.

Automobile manufacturing and maintenance: Used for sealing engines, gearboxes, and exhaust systems, with capabilities to withstand high temperatures and vibrations.

Power and thermal equipment: Suitable for high-temperature sealing parts such as boilers, heat exchangers, and steam valves.

Food and pharmaceutical machinery: Eco-friendly and non-toxic, suitable for sealing parts of equipment requiring high cleanliness.

With the upgrading of industrial technology and the deepening of environmental protection concepts, compressed non asbestos gasket materials have gradually become the new standard in the sealing industry. They not only replace traditional asbestos gaskets but also provide stable and reliable sealing support for various demanding working conditions with their outstanding comprehensive performance and environmental advantages. If you are looking for high-performance, eco-friendly, and durable sealing solutions, Junma's bulk gasket material is undoubtedly a trustworthy choice.