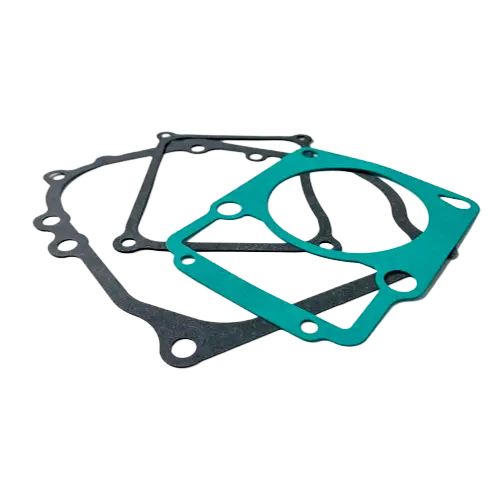

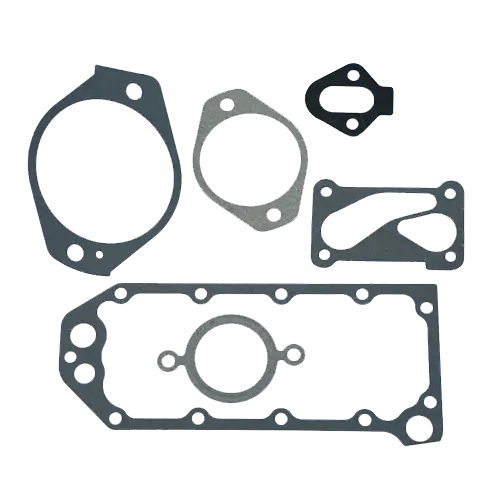

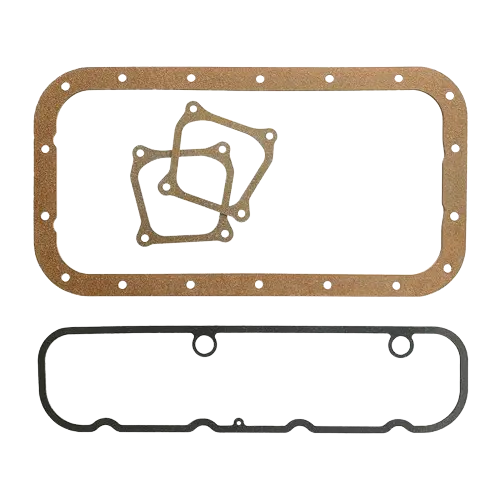

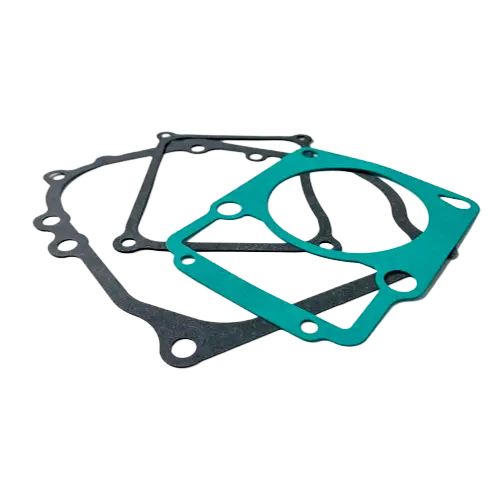

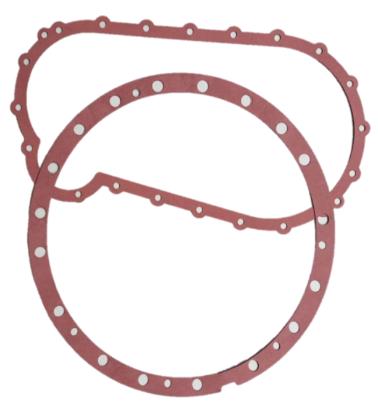

For applications requiring seals on low-pressure flanges and rougher flange surfaces, such as seals for fuel components involving lubrication, Junma's S-series is the best choice. It can be applied to automobiles, motorcycles, general machinery, refrigeration compressors, construction machinery, diesel engines, gearboxes, etc.

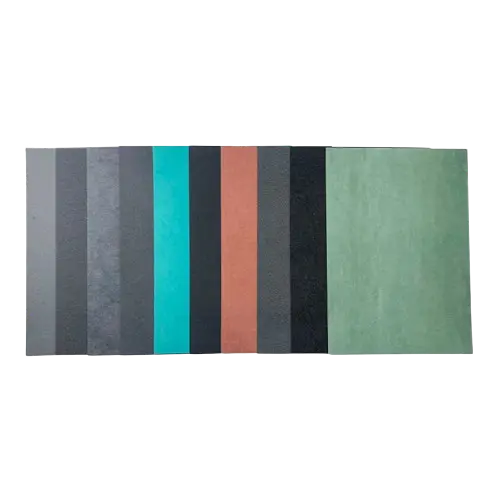

S series deisnged for sealing lubricant oil and fuel,materials can be vulcanized or not vulcanized according to customer's applications.

The applicable temperature for this series products is -40℃ to 300℃.3.Enhanced Tensile Strength: Built to withstand higher internal pressures and vibration without tearing or blowing out.

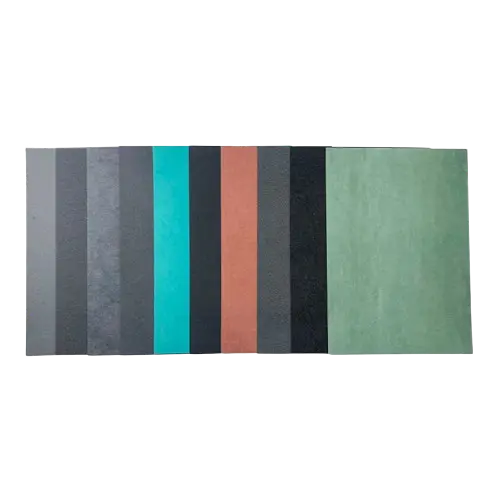

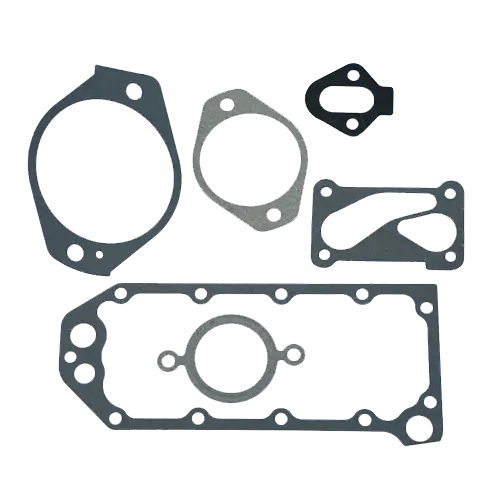

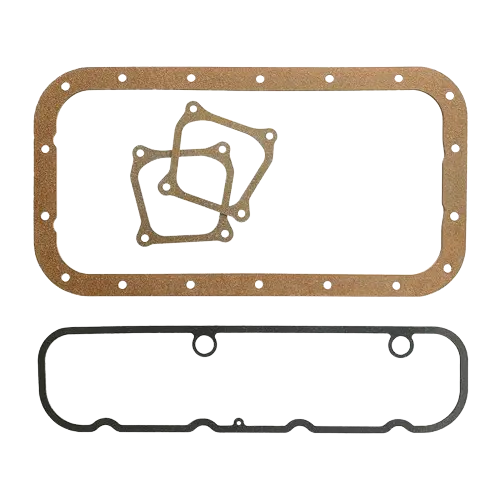

Meet the S-Series Family: S01, S02, S03

We have tiered the S-Series to offer precise solutions for varying operational intensities.

Model S01: The Standard controlled swelled material

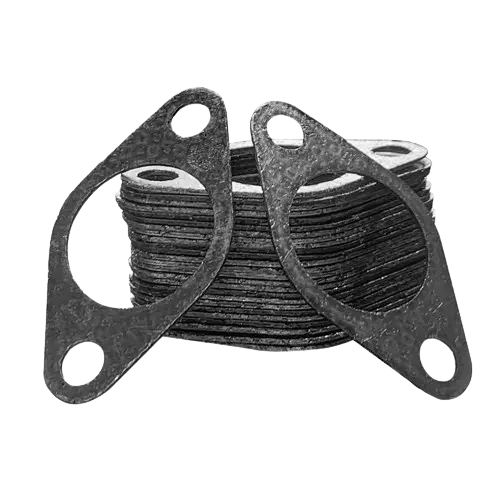

JM-S01 is an asbestos free beater addition sealing material comprised of a blend of aramid and synthetic fibers,and a high quality SBR binder system.JM-s01 is a controlled-swell sealing material with excellent compressibility and recovery properties.It is designed for sealing parts involving lubrication oil and fuel;including automotive,motorcycles,small engines,diesel engines,transmission system,and industrial machinery applications. The material can provide excellent seal at low flange pressure and non-uniform flange surface.

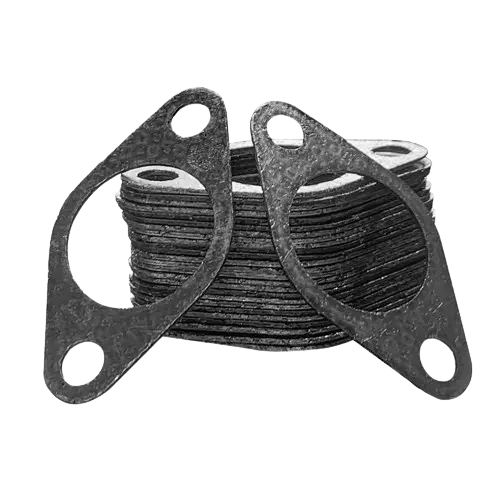

Model S02: The cost effective controlled swelled material

S02 is a cost effective,controlled swelled non-asbestos sealing materials. Its composition is comprised of a high-quality styrene butadiene rubber binder,fibrillated synthetic fibers,and specifically selected inorganic fillers.This products is designed for sealing lubricant oil and fuel.Materials can be vulcanized or not vulcanized according to customer’s applications.

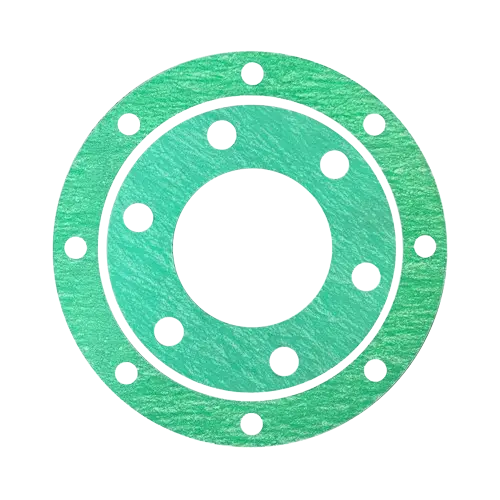

Model S03: The high grade controlled swelled material

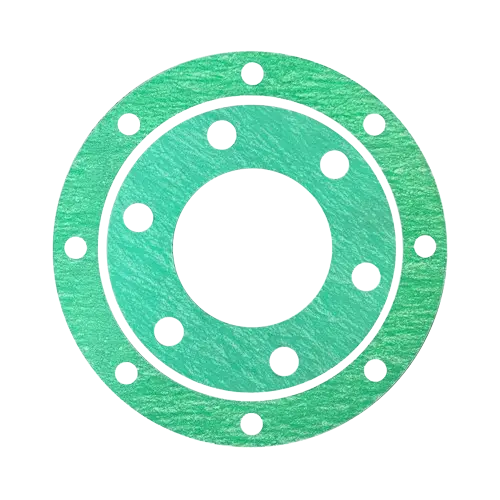

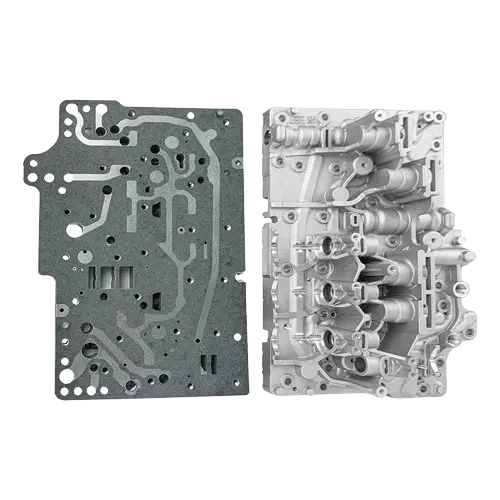

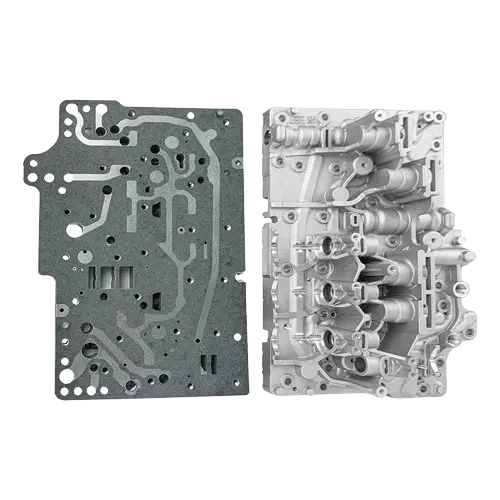

JM-S03 is a high grade asbestos free sealing material with controlled-swell characteristics.It has excellent compressiblity and recovery and can seal parts with low flange pressure and nonuniform flange surfaces. The materials is designed to provide sealability for oil,fuel,and antifreeze fluids. Recommended applications include automobiles,motorcycles,small engines,refrigeration compressors,construction machinery,diesel engines and auto transmissions.

Technical Comparison

To help you select the right grade for your production line, compare the key properties below:

Feature | Model S01 | Model S02 | Model S03 |

Density(g/cm³ | ≥1.2 | ≥1.3 | ≥1.35 |

Compressibility(34.5MPa) | 10-25 | ≥13 | ≥12 |

Tensile Strength (MPa) | ≥8.0 | ≥12 | ≥10 |

Recovery (%) | ≥30 | ≥45 | ≥45 |

Max Temperature | ~250°C | ~300°C | ~300°C |

Strategic Applications: Who Needs the S-Series?

The S-Series is not just for aftermarkets; it is an OEM-ready material.

1.Automotive Manufacturing:

2.Compressors and Hydraulics:

3.Motorcycles & Small Engines:

Conclusion: Upgrade Your Reputation

In the gasket business, your reputation relies on the seal holding. While Economy sheets save money on the front end, the S-Series saves money on the back end by reducing warranty claims, failures, and dissatisfied customers.

For distributors looking to target the Automotive Aftermarket or OEM Machinery sectors, stocking the S-Series is a strategic necessity.

Experience the Premium Difference

Don't compromise on your critical components. Request a comparison kit to feel the difference in density and finish between our E-Series and S-Series.