Author: Lili Reviewer:Dezhong Huang Date: June 11, 2025

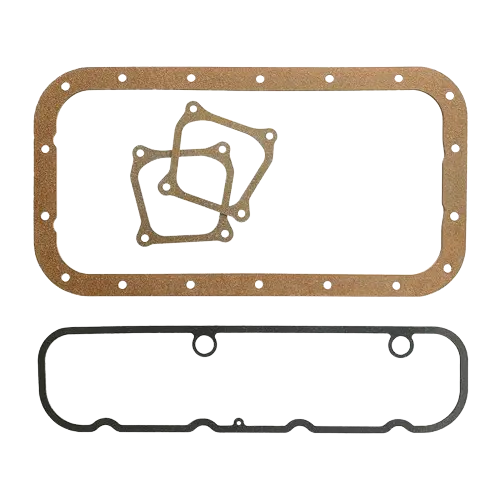

During its use, the gasket may be subjected to lateral forces generated by the expansion of the flange. How far can the gasket be pulled laterally without tearing? The answer is found in the tensile strength of the sealing material.

Tensile strength is a measure of manufacturing quality, and it also indicates the sealing material's resistance to blowout in applications with high wind pressures. Tensile strength is also an important property during cutting, manufacturing and installation.

Tensile strength is measured by the tensile force in the plane of the gasket material rather than the force perpendicular to the gasket sheet. It represents the maximum tensile stress applied during the rupture of the tensile specimen, which depends on the width and thickness of the specimen.

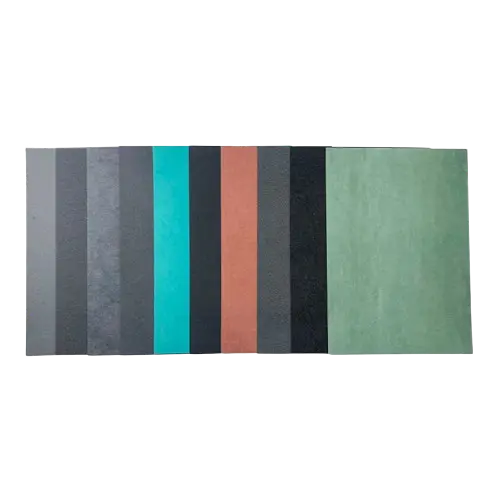

The measurement of tensile strength can identify the tensile strength characteristics of different types of gasket materials. In this way, it provides manufacturers with a measure of product uniformity. The tensile strength of fiber gasket materials ranges from 250psi for some cellulose fiber-based grades to more than 3000psi for high-performance grades.

Fully cured gasket materials typically exhibit higher tensile strength than those that are partially cured or uncured during application. However, in-situ curing allows the gasket to solidify during the initial operation of the equipment.

In the general fiber gasket manufacturing process, tensile strength is often directional, so the tensile strength test should be measured in both directions. Junma Sealing Technology's manufacturing process always strives to ensure that the material has uniform tensile strength in the machine direction (MD) and the entire machine direction (AMD). The tensile strength test is determined using the standard ASTM test method F-152-87. Uniform tensile strength can indicate the material's stable and consistent blowout resistance and tear resistance.