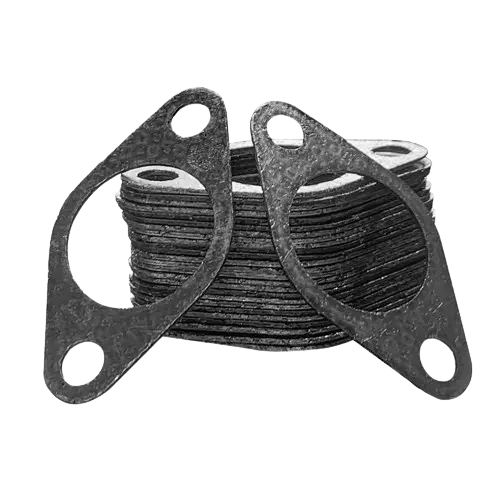

Selecting the suitable fiber sealing material requires a comprehensive consideration of multiple key factors to ensure it meets performance, environmental, and cost requirements in practical applications. The main factors are as follows:

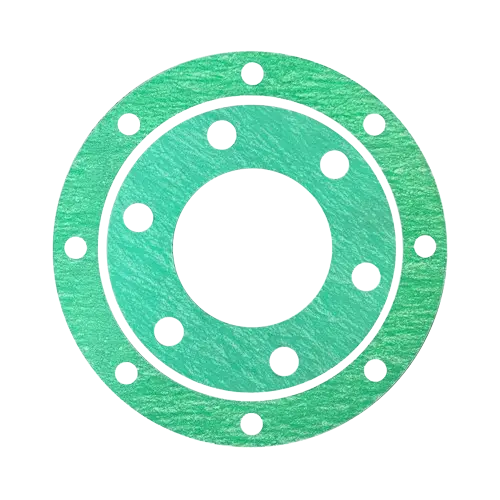

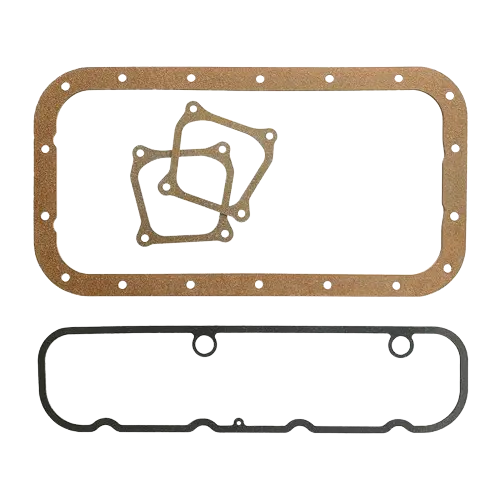

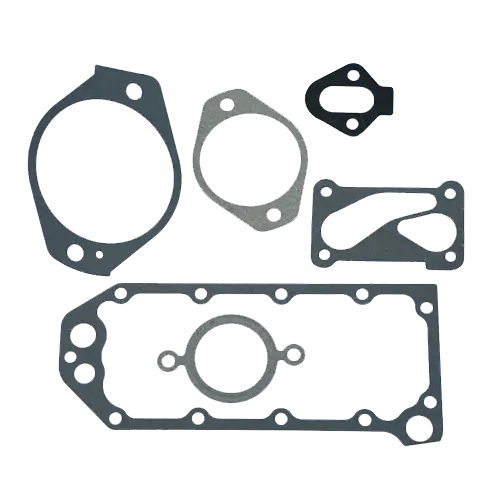

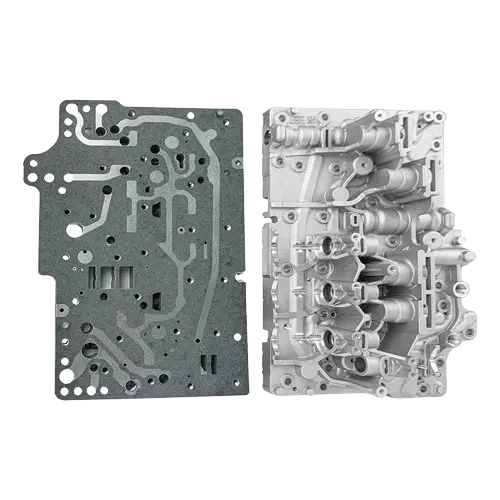

Fiber Sealing Material Operating Environmental Conditions

Temperature range: The material must withstand the maximum and minimum operating temperatures.

Exposure to media: Resistance to chemical corrosion from acids, alkali, oils, solvents, or oxidizers.

Pressure and load: Dynamic or static pressure, mechanical vibrations, etc.

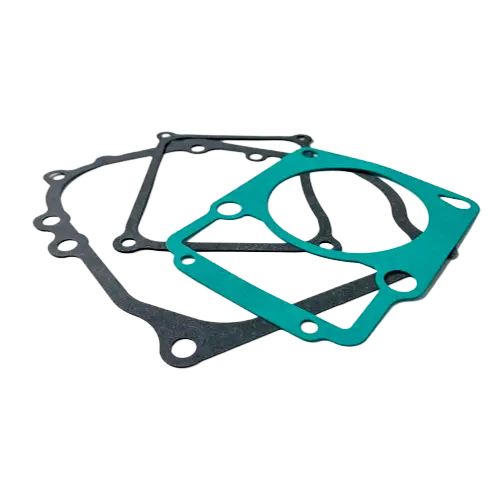

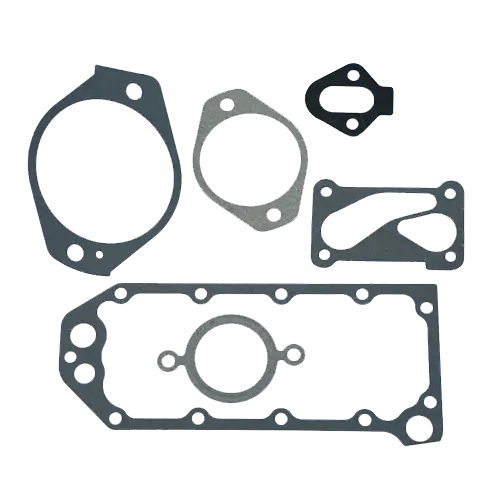

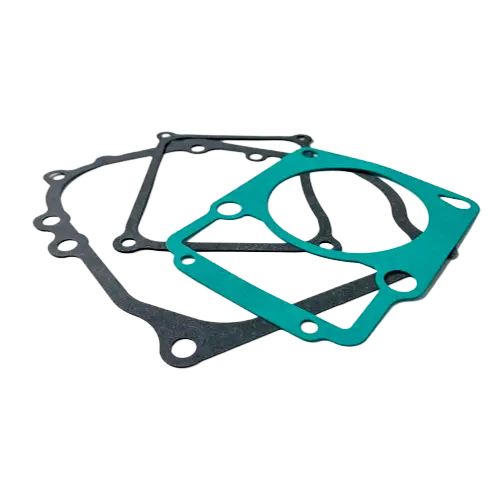

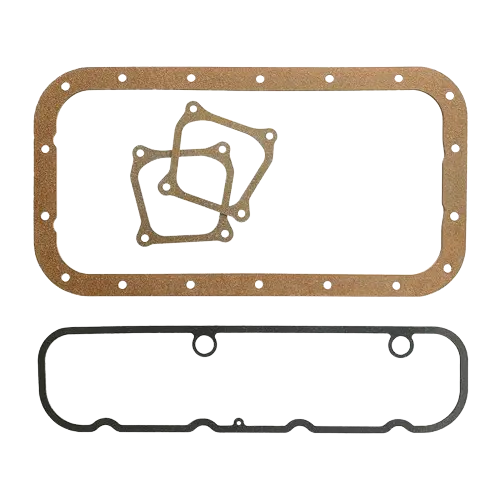

Fiber Sealing Material Performance Requirements

Sealing performance: Porosity, compression resilience (e.g., expanded graphite fiber offers excellent sealing).

Wear resistance: For high-friction scenarios (e.g., aramid fiber has strong wear resistance, making it suitable for dynamic sealing).

Strength and flexibility: Tensile strength, tear resistance (e.g., glass fiber has high strength but is brittle, while polyester fiber is more flexible).

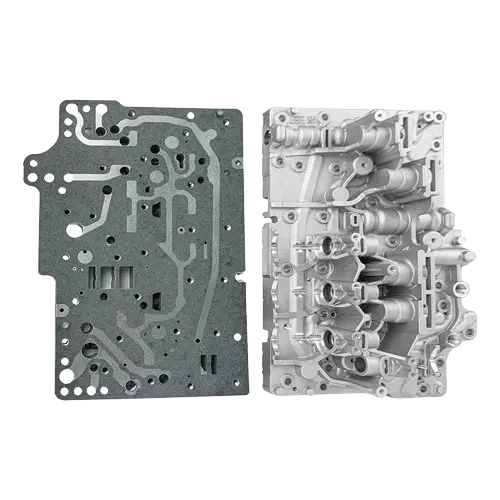

Thermal conductivity/insulation: Some applications of the fiber gasket require thermal conductivity (e.g., metal fibers) or insulation (e.g., ceramic fibers).

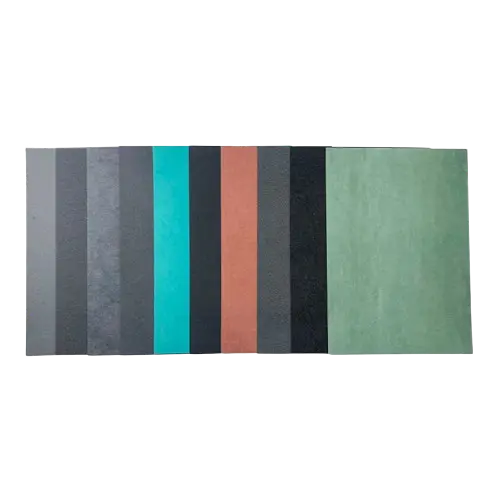

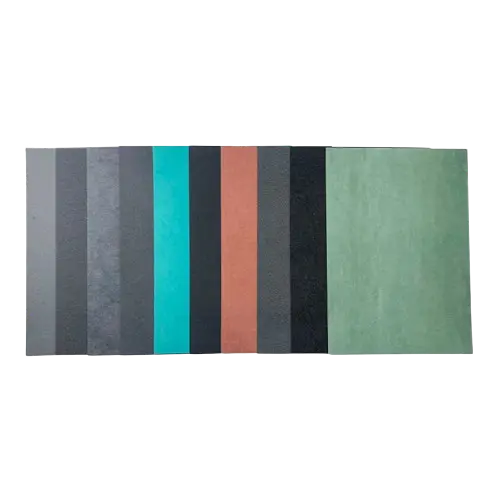

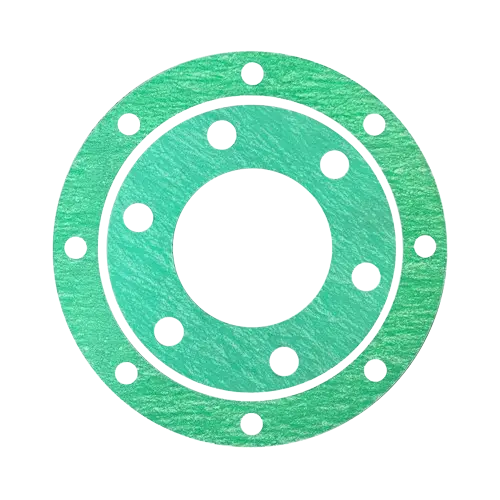

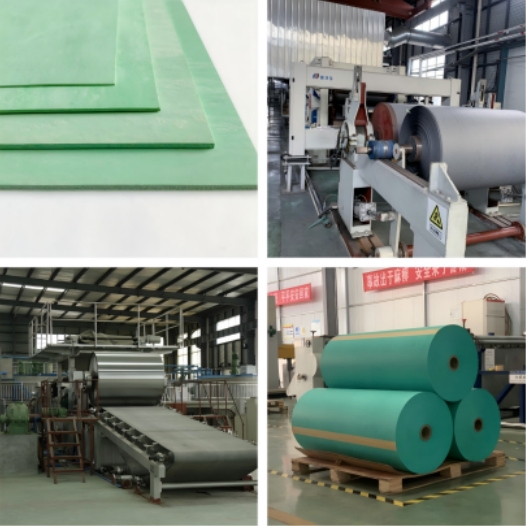

Fiber Sealing Material Types and Characteristics

Inorganic fibers (e.g., glass, ceramic fibers): High-temperature resistance but brittle.

Organic fibers (e.g., aramid, PTFE): Good chemical stability but limited temperature resistance.

Carbon fiber: High strength and corrosion resistance, but expensive.

Natural fibers (e.g., cellulose): Eco-friendly but less durable.