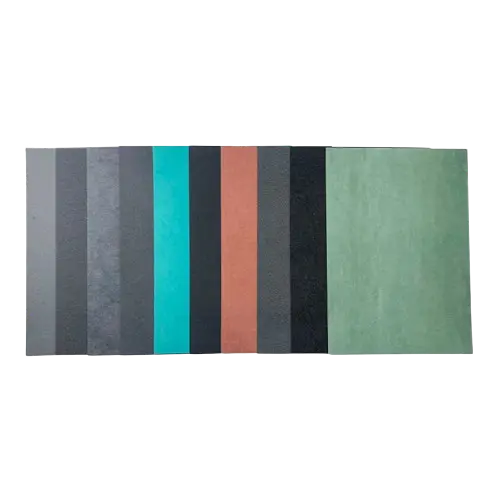

I am Qiongxiou Ma, the founder of Junma Sealing Technology. Junma Sealing focus on the production and research and development of sealing materials. We have 30 patents, including 7 invention patents.We have a group of well-known companies in the industry who have been cooperating with us since we founded. Our technical team and R&D team communicates deeply with the customer's technical team and enters the customer's production workshop to understand their product applications, and further understands the customer's requirements for our sealing materials, so as to provide customers with more accurate and effective materials. 28 years have passed, and we have achieved fruitful results together.

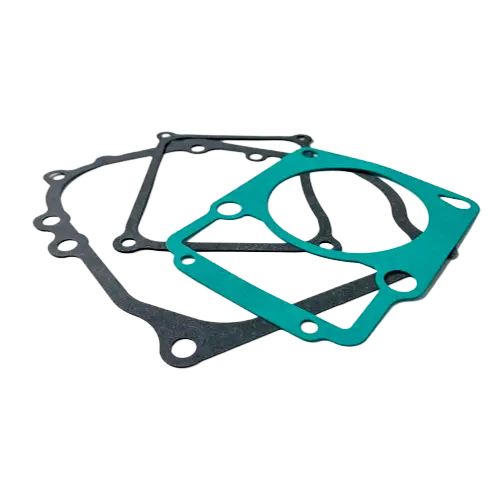

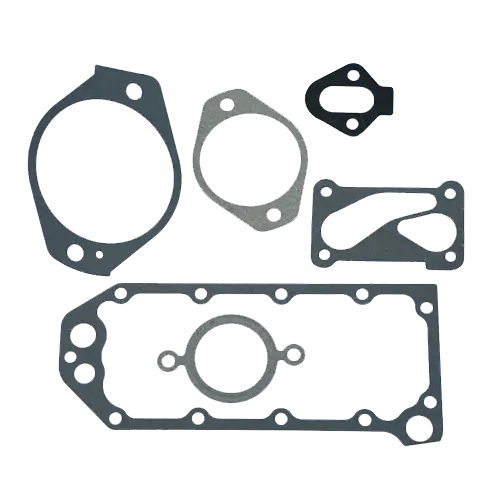

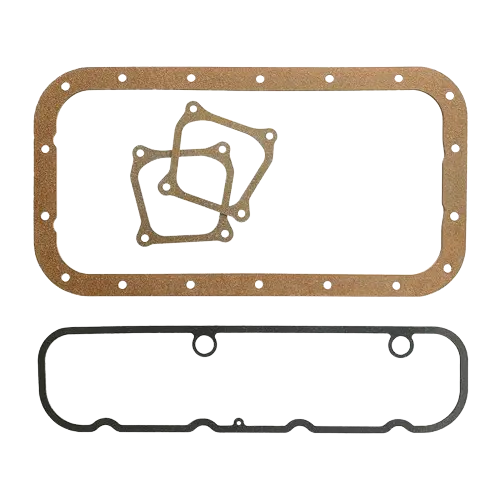

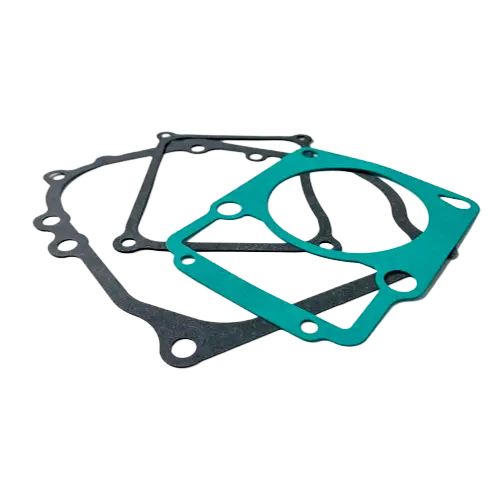

The development of every enterprise is inseparable from the long-term support and in-depth cooperation of high-quality suppliers. As a sealing material user,First of all, we must recognize the importance of sealing materials,In industries ranging from automotive and aerospace to oil & gas and pharmaceuticals, sealing materials play a critical role in ensuring system integrity, preventing leaks, and enhancing operational efficiency. However, the performance of these materials depends not only on their inherent properties but also on the reliability of the supplier providing them. Selecting an excellent sealing material supplier is crucial for long-term success, cost efficiency, and risk mitigation. Following is some of my suggestion for choosing a good sealing material supplier.

Key Criteria for Selecting a Sealing Material Supplier

✔ Industry experience and reputation – Look for proven expertise in your sector.

✔ Quality certifications – Ensure compliance with international standards.

✔ Technical support – Assess their ability to provide application-specific solutions.

✔ Supply chain reliability – Check lead times, inventory management, and contingency plans.

✔ Cost vs. value – Balance price with long-term performance benefits.

A High quality Sealing Material Supplier can Provide:

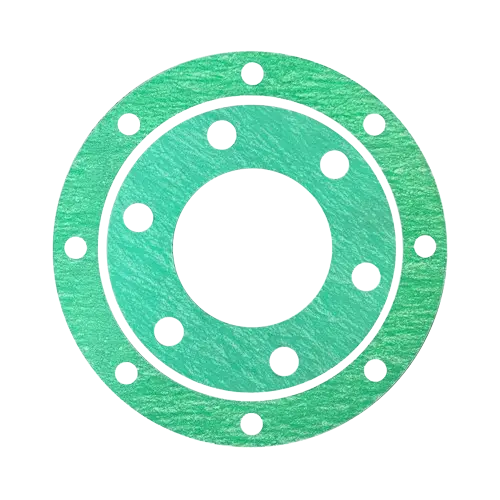

1. Ensures Material Quality and Consistency

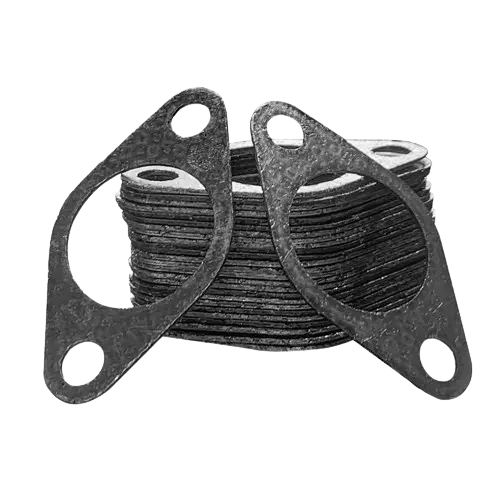

Reputable sealing and gasket material suppliers adhere to strict quality control standards, ensuring that sealing materials meet precise specifications. Inconsistent material quality can lead to premature failure, leaks, or even catastrophic equipment damage.

2. Provides Technical Expertise and Support

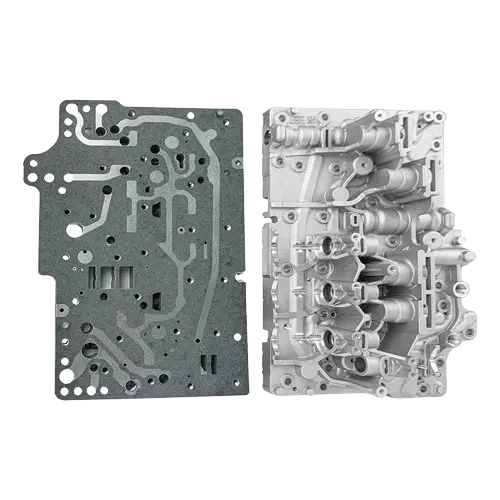

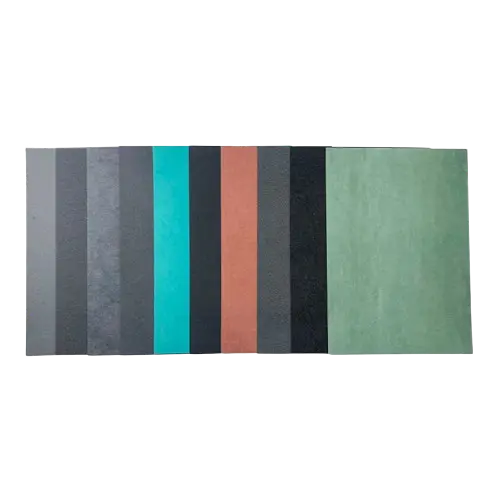

Material selection guidance- Choice a suitable material according to your application

Custom formulations – Tailors materials for unique application

Failure analysis – Assists in diagnosing and resolving sealing issues.

3. Reduces Supply Chain Risks

On-time delivery- Prevents production delays.

Stable inventory- Avoids shortages of critical materials.

Traceability- Provides documentation (e.g., material certifications, batch tracking) for compliance and safety.

4. Enables Innovation and Future-Proofing

A good suppliers must invest in R&D, offering advanced materials hat improve performance and sustainability. Partnering with such suppliers keeps businesses competitive.

Choosing the right sealing material supplier is not just a procurement decision—it’s a strategic investment in operational reliability, safety, and efficiency. A high-quality supplier ensures superior materials, technical support, and supply chain stability, ultimately reducing risks and enhancing performance. By prioritizing supplier excellence, businesses can achieve long-term success in demanding industrial environments.