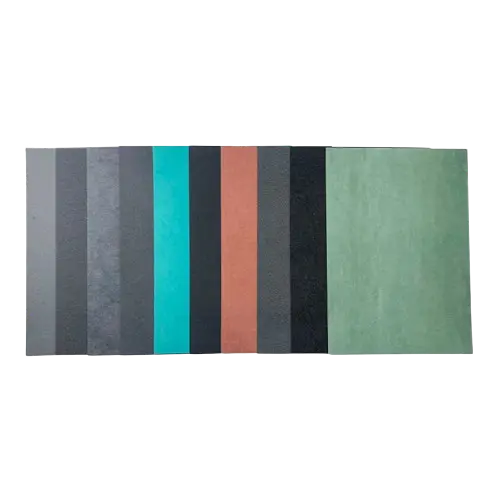

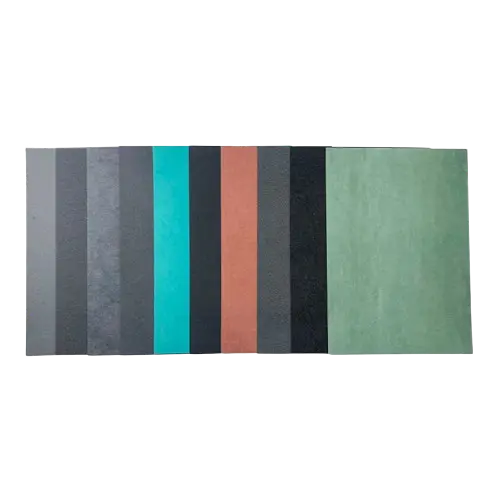

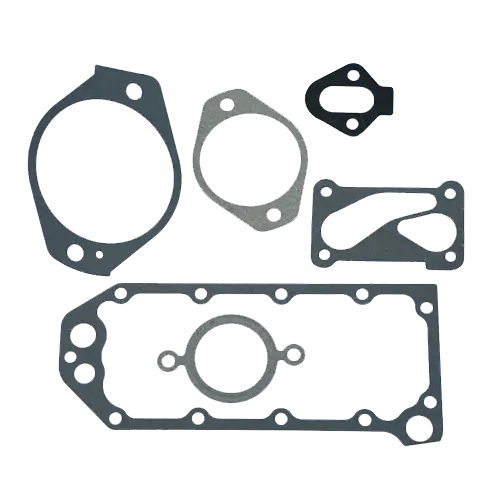

Cork rubber gasket material is a composite material that combines rubber and cork particles, formed through vulcanization and mixing processes. This material fuses the flexibility of rubber with the high compressive resilience of cork, offering a range of excellent properties that make it an ideal choice for various sealing applications. Below, we will delve into the main characteristics of cork rubber sheets.

Excellent Oil Resistance of the Cork Rubber Gasket Material

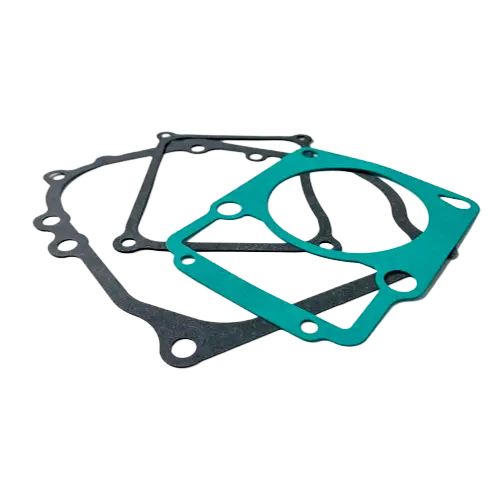

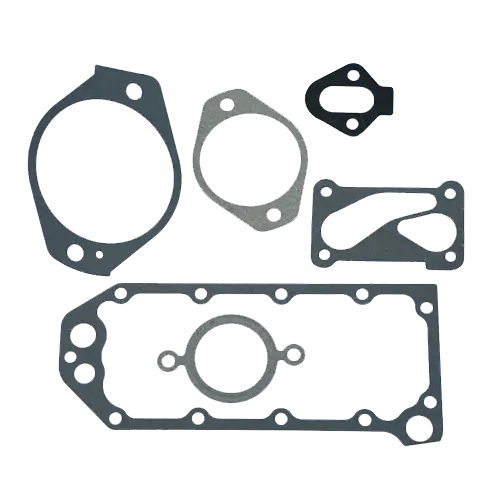

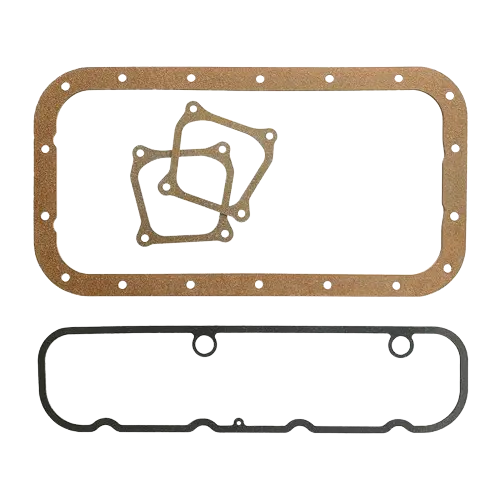

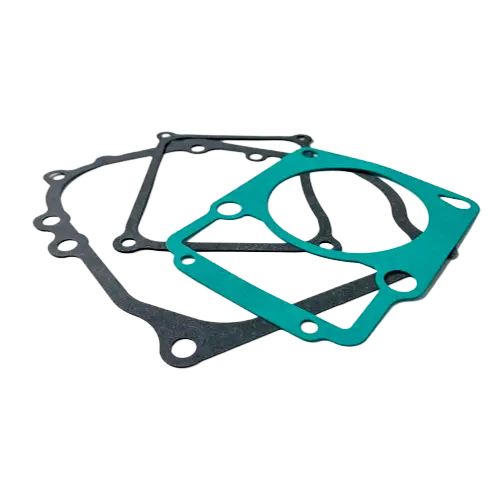

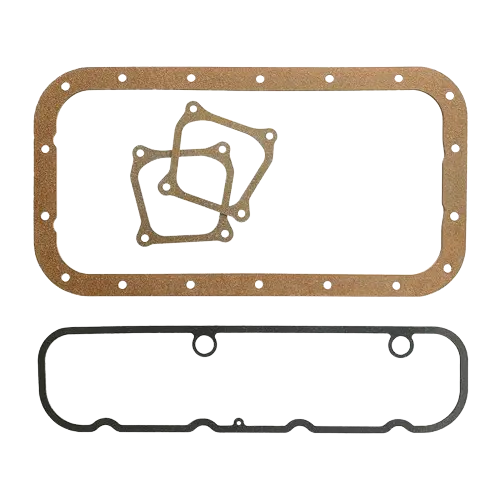

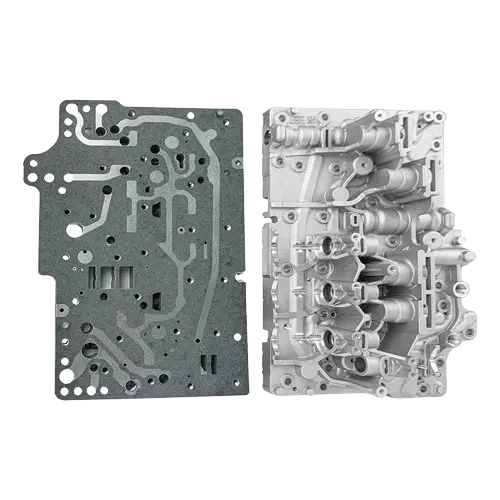

Cork rubber gasket material performs outstandingly in terms of oil resistance. Cork barely reacts with oils, making cork rubber sheets, which contain rubber, highly oil-resistant. Even after prolonged immersion in oils, the dimensional stability of cork rubber products remains intact, preventing corrosion and deformation caused by oils. This makes them widely applicable in sealing parts like oil pans in automobiles, motorcycles, and mechanical equipment.

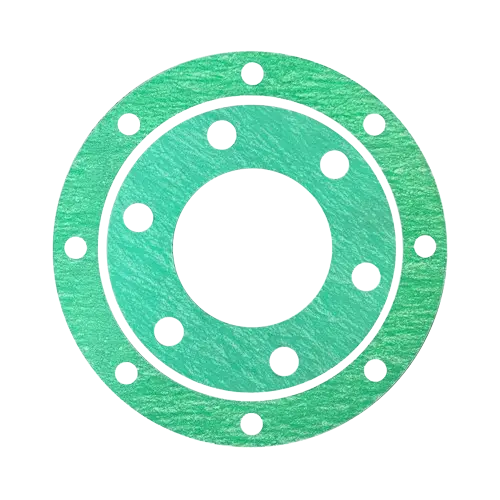

Good Compressibility and Resilience of the Cork Rubber Gasket Material

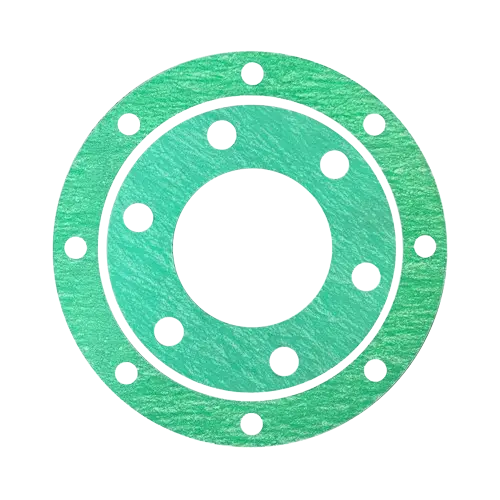

Another significant feature of cork rubber sheet material is its excellent compressibility and resilience. The microscopic structure of cork is filled with air cells, and when combined with rubber, it forms natural microbubbles. This structure allows the gasket to effectively deform under pressure and quickly return to its original shape once the pressure is released, providing cushioning and sealing functions. With increased cork content, the compressibility of the cork rubber sheet decreases while resilience increases, further enhancing sealing effectiveness and service life.

Outstanding Acoustic Properties of the Cork Rubber Gasket Material

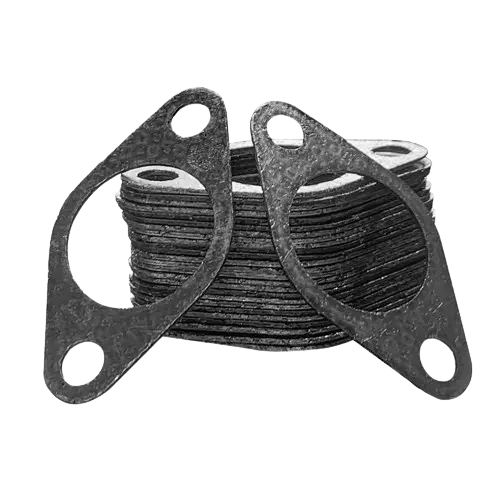

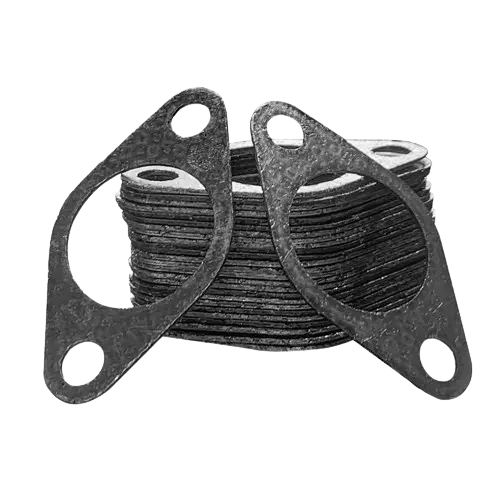

Cork rubber gasket material also possesses excellent acoustic properties. Due to the unique structure of cork, it can effectively absorb sound waves and reduce noise. In automobiles, machinery, and other equipment, cork rubber sheets serve as a cushioning material that helps reduce vibration and noise, providing a quieter operating environment.

Strong Impact Resistance and High Tensile Strength of the Cork Rubber Gasket Material

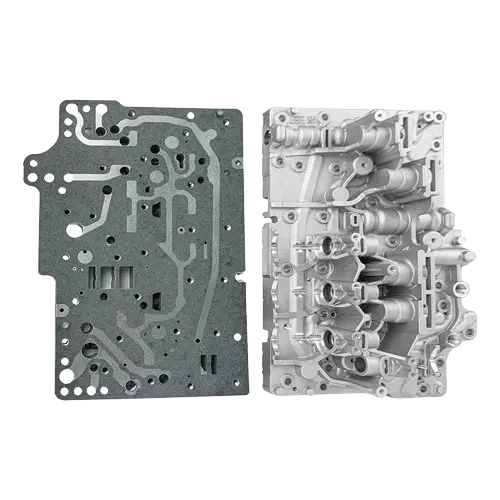

Not only does cork rubber sheet material excel in static sealing, but it also demonstrates remarkable impact resistance and tear resistance under dynamic conditions. It can effectively withstand impacts and vibrations during equipment operation, maintaining its sealing performance. Specifically, by varying the granule size and proportion of cork with rubber in the cork rubber sheet material, the tensile strength, hardness, and elongation of the gasket can be adjusted to meet the sealing requirements under different working conditions.

Good Damping Properties and Friction Coefficient of the Cork Rubber Gasket Material

Due to the special structure of cork rubber, cork rubber sheet material has a high friction coefficient, providing effective damping and reducing damage caused by vibrations. Additionally, this material can reduce wear caused by friction, extending the service life of both the equipment and the gaskets. It is widely used in mechanical equipment, particularly in applications requiring shock absorption and damping, such as engine and diesel engine cylinder head gaskets and oil pans.

As a high-performance sealing material from the professional custom gasket suppliers, cork rubber sheets display oil resistance, water resistance, aging resistance, good resilience, and strong impact and damping properties. They are widely used in automobiles, motorcycles, general machinery, and diesel engines, among other industries. Whether in oil resistance, aging resistance, or in vibration and noise control, cork rubber sheet material offers unmatched advantages over traditional materials, making it an indispensable sealing solution in modern industrial fields.