In the fluid sealing industry, the global transition away from asbestos is complete. However, for many gasket distributors and industrial buyers, a significant challenge remains: finding a material that replaces the affordability of asbestos without sacrificing critical sealing performance.

While high-end synthetic fibers offer exceptional durability, they often exceed the budget for general-purpose applications. To bridge this gap, Junma Seal introduces the Non-Asbestos Gasket Paper E-Series—a solution engineered to deliver the optimal balance between price and performance.

The Challenge: Over-Engineering vs. Reliability

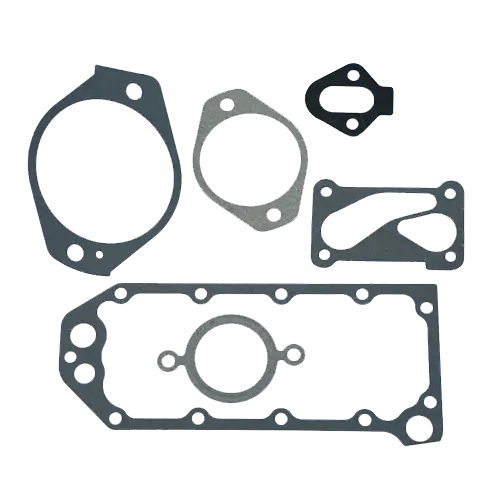

Not every flange requires a premium, high-cost gasket. Using top-tier aramid fiber sheets for low-pressure or standard flanges is often an unnecessary expense (over-engineering). Conversely, choosing low-quality substitutes can lead to leakage, downtime, and safety hazards.

The market needs a "workhorse" material. This is where the E-Series fits in. It is designed specifically for MRO (Maintenance, Repair, and Operations) and general manufacturing sectors that require reliable sealing at a competitive price point.

What is the E-Series Non-Asbestos Sheet?

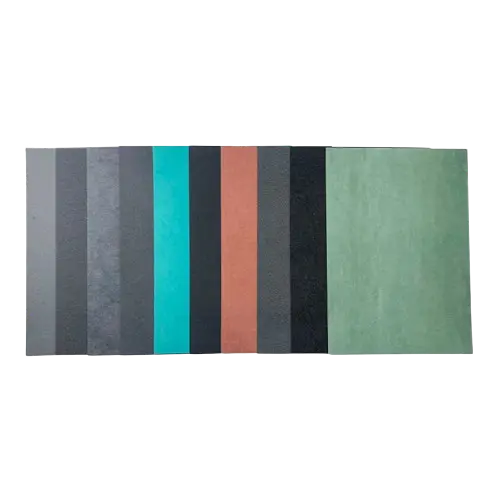

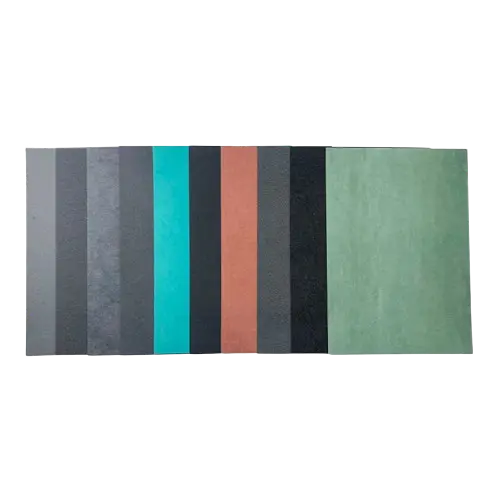

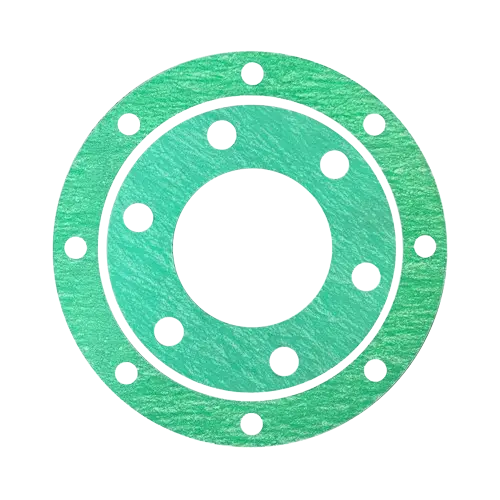

The E-Series is our standard-grade non-asbestos jointing sheet. It is manufactured using a composite of organic fibers, mineral fibers, and a high-quality NBR (Nitrile Butadiene Rubber) binder.

Because NBR is the primary binder, the E-Series exhibits excellent resistance to oils, fuels, and hydrocarbons, making it significantly more versatile than sheets bound with SBR (Styrene Butadiene Rubber).

Technical Specifications at a Glance:

Feature | Specification | Impact on Performance |

Binder Type | NBR (Nitrile) | Superior oil and fuel resistance |

Max Temperature | 200°C - 250°C | Covers most general industrial heat ranges |

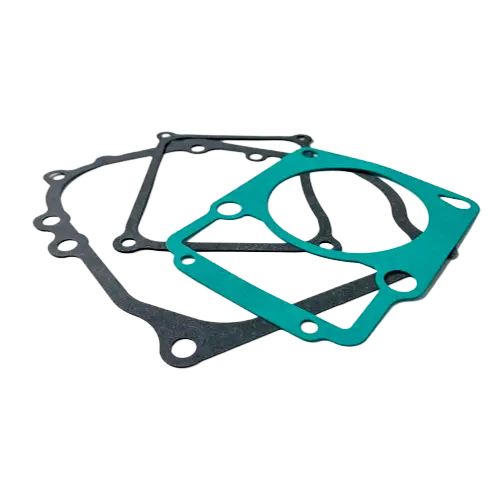

Color Options | Green, Blue, Black | Customizable for brand identification |

Dimensions | 1320x970mm / 1.2x400m | Large sizes maximize yield for gasket cutters |

3 Reasons to Switch to the E-Series

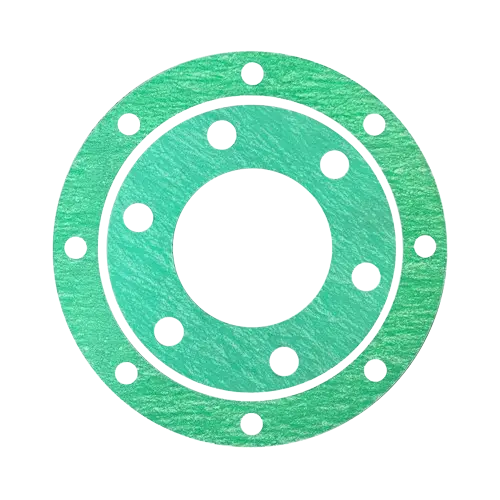

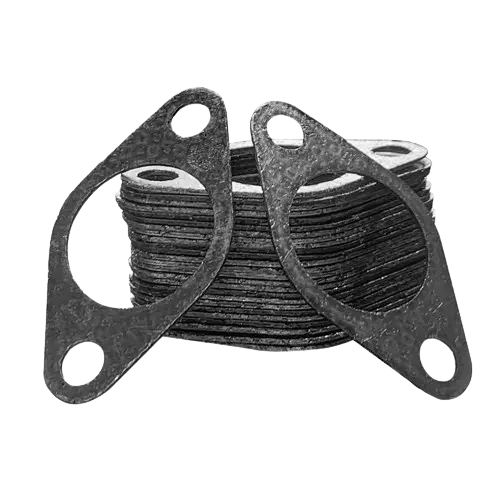

1. Superior Machinability for Gasket Cutters

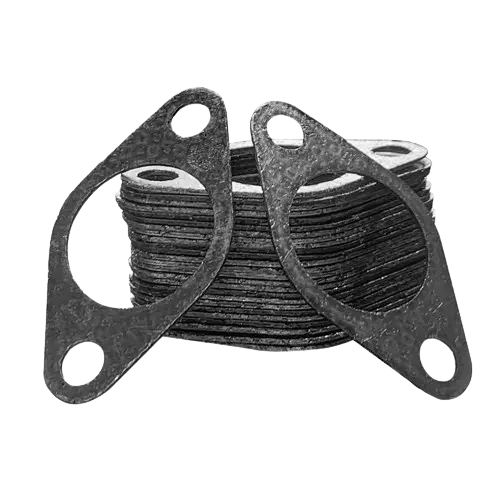

For gasket cutting factories, material waste is a major cost factor. The E-Series is produced with a uniform density structure. This ensures clean edges during die-cutting or laser cutting, minimizing fraying and ensuring that intricate gasket shapes maintain their integrity. We offer large sheet sizes (e.g., 1500x2000mm) to maximize your cutting yield.

2. Verified Compliance and Safety

Transitioning to non-asbestos materials is largely driven by health and safety regulations. The Junma Seal E-Series is 100% Asbestos-Free. It complies with international environmental standards, making it safe for export to strictly regulated markets in Europe and North America.

3. Optimized Cost-Performance Ratio

We understand that price sensitivity is a reality in today's supply chain. The E-Series is positioned as an "Economy" line. By optimizing our fiber mixture and manufacturing process, we provide a sheet that rivals competitors' mid-tier products at a much more attractive price point.

Ideal Applications

Where should you specify the E-Series? It is the ideal choice for:

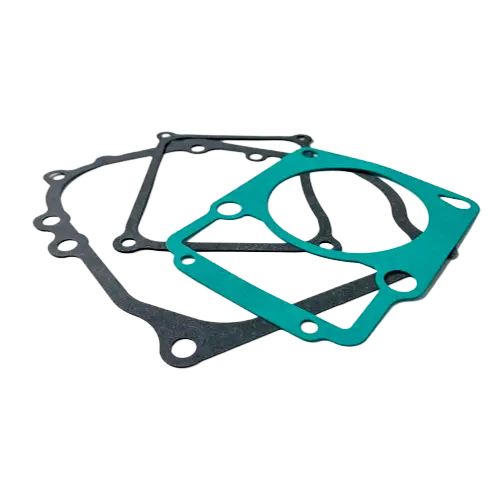

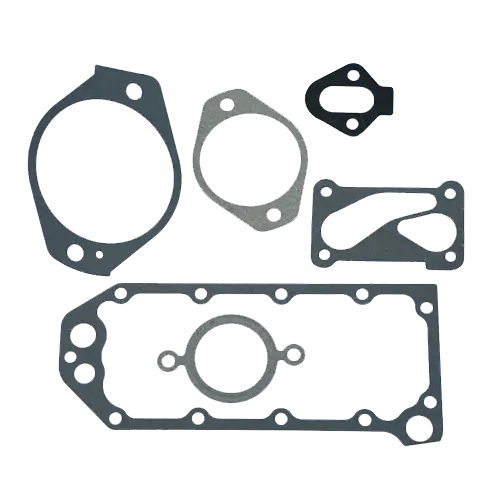

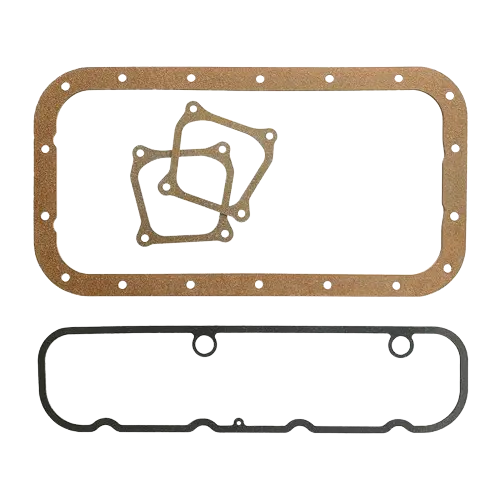

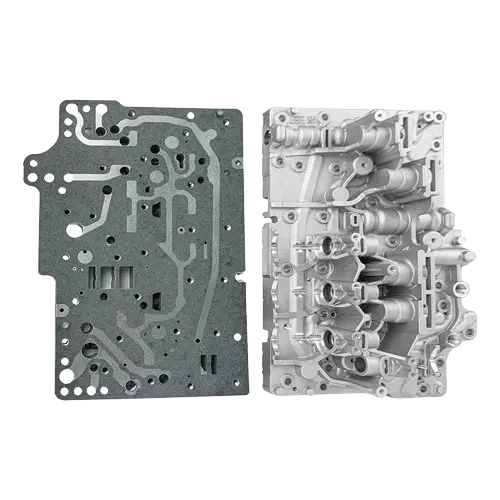

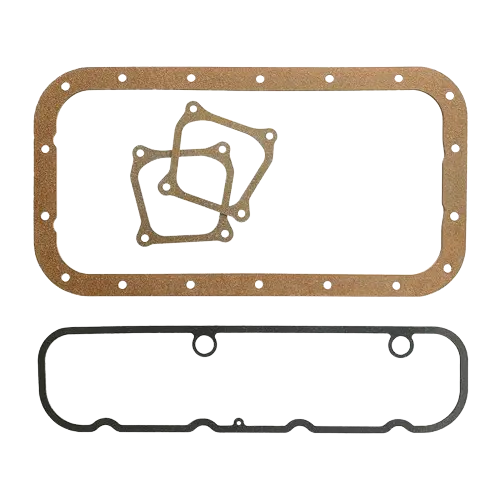

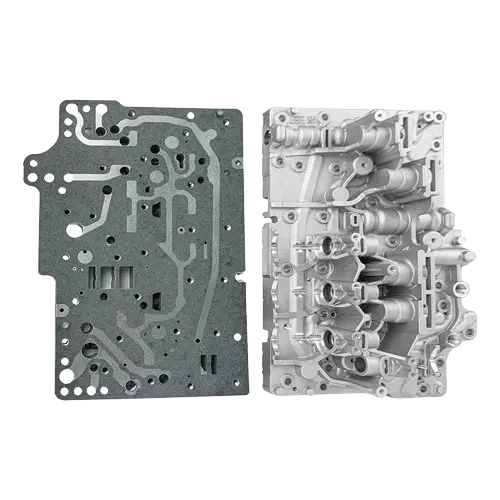

Light Machinery: Gearbox covers and pump casing seals.

Automotive Aftermarket: Cost-effective solutions for engine ancillary gaskets where oil resistance is required.

HVAC Systems: Sealing duct work and heating components.

Conclusion: The Rational Choice for Bulk Supply

When your project demands a reliable seal but the budget is tight, you shouldn't have to compromise on quality. The Non-Asbestos Gasket Paper E-Series proves that you can have a dependable, oil-resistant sealing solution that protects your bottom line.

At Junma Seal, we are committed to helping you find the right material for the right application.

Ready to test the quality? Don't just take our word for it. Contact our technical team today to request a Free Sample Kit of the E-Series and see the difference yourself.